15% Cobalt YG15 Tungsten Carbide Cold Heading Dies For Cold Heading Machine

HengRui Cemented carbide is a professional manufacturer of cemented carbide in China. The company is committed to research & development, production and sales of new material and new products of cemented carbide. So far we have developed several series of major products includes cemented carbide rods, plates, moulds, dis cutter, mining tools and other special tailors. What's more our products have been granted the confirmity of ISO9001:2008. You need not worry about our product quality.

| Tungsten Carbide Cold Forging/heading Dies | ||||

| Grades | Density | T.R.S | Hardness | Performance & application recommended |

| g/cm³ | MPa | HRA | ||

| YG11 | 14.4 | ≥3000 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. |

| YG15 | 14 | ≥3400 | 87.5 | For fabricating drawing dies of steel tubes and rods under High compressibility ratio; punching, stamping, forging tools under large stress. |

| YG20 | 13.5 | ≥3800 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps. |

| YG15C | 14 | ≥4000 | 86.5 | For oil cone drill bits, cut medium soft and hard rocks; debarking and cutting of frozen wood, soft wood and original wood. |

| YG16C | 13.9 | ≥3500 | 85.5 | Impact resistance forging dies. |

| YG18C | 13.7 | ≥3600 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. |

| YG20C | 13.5 | ≥3800 | 83.5 | Dies for wear resistant or impact resistant application. |

| YG22C | 13.3 | ≥4000 | 83 | Nut forming dies and high impact resistance forging dies. |

| YG25C | 13.1 | ≥4250 | 82.5 | Stainless bolt header dies and rollers. |

1. Professional mechanical & chemical inspecting labs to control the quality

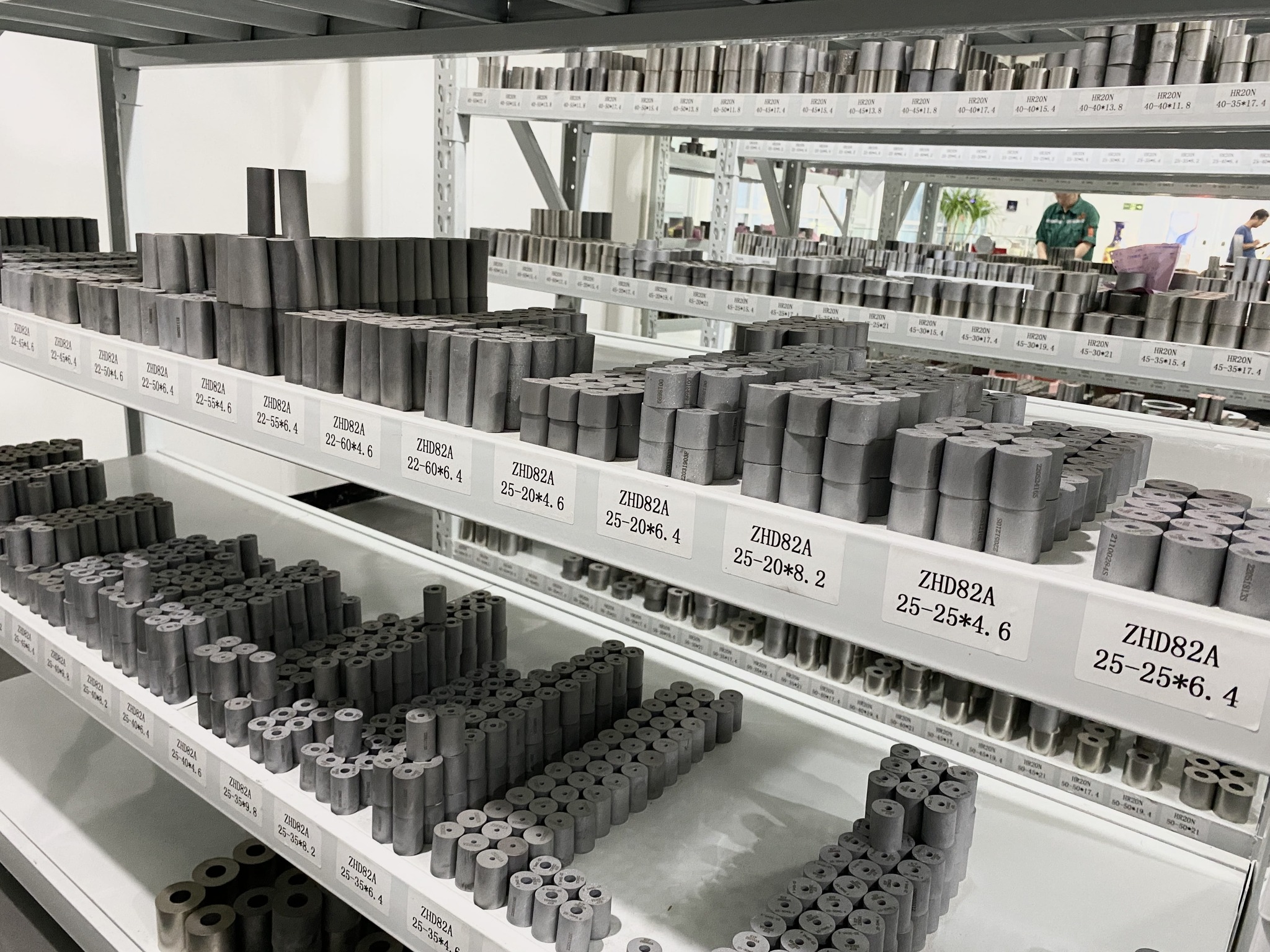

2. Full range of types available ,meet customre's different requirements.

3. Stable quality, short delivery time with competitive price

4. High accuracy with long service life

5. Professional package, protecting the products from damage

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% before delivery. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.