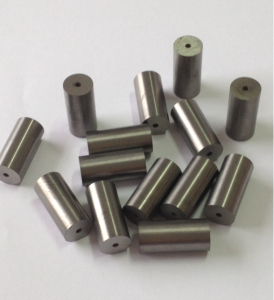

Vitenam Popular ST7 HR022 HR004 tungsten carbide cold heading die for M2~M8 screw mold

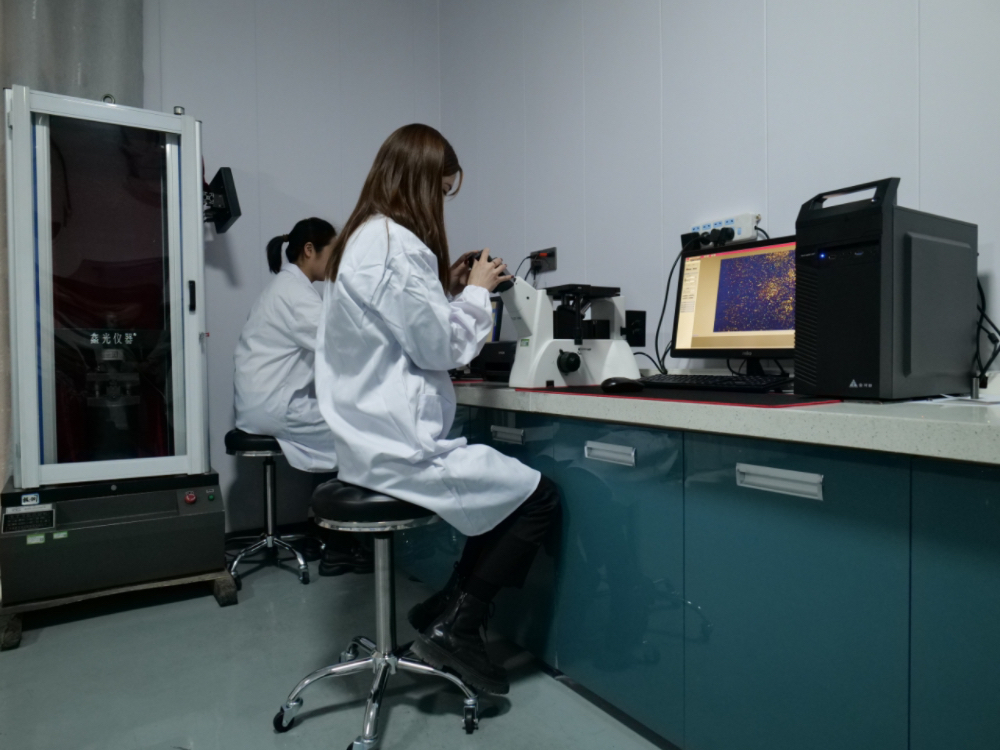

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

CARBIDE GRADE

Principles of material selection for tungsten carbide cold heading molds

1. Mechanical properties: Cold heading dies need to have high hardness and strength to ensure that they can withstand large impacts and pressures during the high-speed cold process. Generally speaking, commonly used materials include alloy steel, high-speed steel, carbide, etc.

2. Wear resistance: The cold heading mold will produce greater friction and wear during use, so it needs to have good wear resistance to extend the service life of the mold. Choose materials with high hardness and good durability, such as high-carbon alloy steel, high-speed steel, etc.

3. Corrosion resistance: The cold heading mold may be exposed to some corrosive media during the cold heading process, so materials with good corrosion resistance need to be selected to prevent the mold from being damaged by corrosion. Alloy steel, stainless steel, etc. have better corrosion resistance.

4. Processing performance: The manufacturing of cold heading dies requires a series of processing techniques, including forging, quenching, grinding, etc. Therefore, materials with good processing properties need to be selected to ensure the accuracy and quality of the molds. Generally speaking, commonly used materials include alloy steel, high-speed steel, etc. that are easy to forge and heat treat.

1.Original manufacture for 19 years

2.Mature Processing department for finished mold

3.Experienced exportation team for direct sale

All together gives you Guaranteed quality Based on competitive price at High Efficiency Delivery

We can send international express such as DHL, FedEx, UPS, SF Express, etc. We can also choose lower-cost shipping methods such as sea transportation and air transportation.

1. How to choose tungsten carbide grade?

When selecting a carbide model, various factors need to be considered, including required physical and chemical properties, application industry and environmental conditions, etc.

2. What grade of tungsten carbide is suitable for cold heading molds?

The material of the cold heading die should have high hardness and strength to ensure processing accuracy and durability. Please tell us your needs. We have rich market experience and can recommend the most suitable grade to you.

3. What are the advantages of choosing us?

We are a direct manufacturer and can give you the lowest price and the best quality. At the same time, we also have more than 30 years of experience in cold heading mold sales and production. We understand the technical elements of each link of cold heading molds, understand markets around the world, and can accurately Determine why the mold is damaged and find a solution.