Cemented carbide is a hard material consisting of a refractory metal hard compound and a binder metal, produced by powder metallurgy, which has high wear resistance and certain toughness. Because of its excellent performance, cemented carbide is widely used in various fields such as cutting, wear-resistant parts, mining, geological drilling, oil extraction, mechanical parts, etc.

Cemented carbide production process is: mixture preparation, pressing and forming, sintering, the 3 main processes. So what is the process like?

Dosing process and principle

Weighing the required raw materials and a small amount of additives, loaded into the rolling ball mill or stirring ball mill, the raw materials in the ball mill to get fine and uniform distribution, and then spray drying, vibration sieving into a certain composition and particle size requirements of the mixture to meet the needs of pressing molding and sintering.

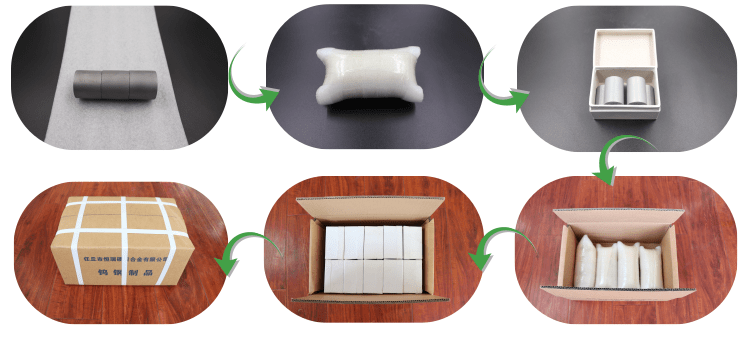

After the completion of pressing and sintering, the rough carbide parts are discharged from the furnace and packed after quality inspection.

Post time: Jun-20-2023