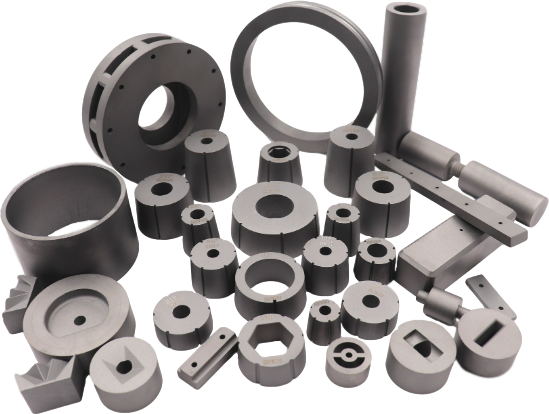

As the name of industrial teeth carbide, most of those who have used it do not know how carbide is produced and what is the difference in its production process, in fact, the manufacturing of carbide is related to its use of the environment. For example, carbide for mining, carbide for rock drilling, carbide turning tools, etc. are all based on environmental use. There are also for example corrosion resistant carbide and so on.

How is Cemented Carbide produced? What is its production process?

The production process of cemented carbide is generally as follows: refractory metal hard compounds (tungsten carbide, tantalum carbide, etc.), bonding metal (cobalt powder or nickel powder) and a small amount of additives (stearic acid or esomin) are mixed and ground in hexane grinding medium, and the slurry of paraffin wax is added, then vacuum dried (or spray dried), sieved, granulated, and made into blended material; the blended material is identified and qualified, and after precision The blended material is identified and qualified, then pressed to make a high-precision press billet; The pressed billet is sintered by vacuum dewaxing or low-pressure sintering to make cemented carbide.

Sintering principle

The vacuum sintering process is carried out by heating under vacuum conditions, which is conducive to eliminating impurities, improving the purity of the sintering atmosphere, improving the wettability of the bonding phase and promoting the reaction. The pressed billet is heated in the vacuum sintering atmosphere, and as the temperature rises and reaches the evaporation temperature, it escapes from the pressed billet and is held for a sufficient time at a partial pressure of paraffin vapor less than that temperature, and the paraffin is discharged from the pressed billet* and recovered, and the pressed billet is purified. As the temperature increases further, the billet is degassed and further purified, and solid-phase sintering ensues. In the solid phase sintering process, the atoms (or molecules) of each component in the sintered body diffuse, the particle contact surface increases, the distance between particles decreases, the sintered body shrinks and is further strengthened. When the temperature is close to the melting point of the bonded phase, the bonded phase starts plastic flow, and when the temperature of the liquid phase is reached, the sintered body produces the liquid phase and liquid phase sintering occurs.

In the liquid phase sintering process, a liquid phase layer appears on the carbide surface, and the carbide particles dissolve in the bonding phase by diffusion to form an eutectic, and the carbide particles recrystallize and grow in size through the liquid phase, so that the adjacent carbide particles are closely linked, and the sintered body shrinks further and densifies rapidly. The sintered body is further shrunk and rapidly densified. It is held at a temperature higher than the sintering temperature of the liquid phase for a period of time in order to allow the sintering process to proceed fully, and then cooled down.

Throughout the sintering process, the sintered body is densified to near non-porosity, and a series of physicochemical effects and organizational adjustments are produced, resulting in the formation of a dense, cemented carbide with a certain chemical composition, physical and mechanical properties, and organizational structure.

Post time: Jun-29-2023