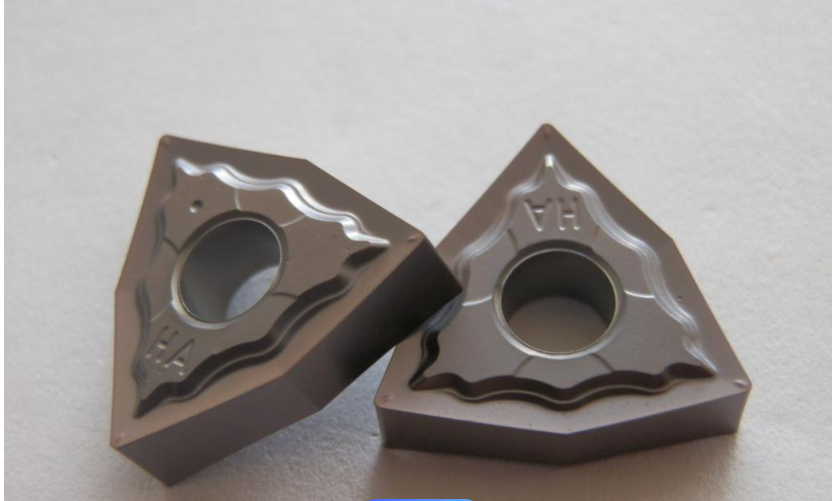

Characteristics of YG8 tungsten steel: Tungsten-cobalt ordinary hard alloy, molding material, is based on refractory metal carbide (such as tungsten carbide, titanium carbide), uses cobalt or nickel as the binder, and is produced by powder metallurgy. As a composite material, cemented carbide has high hardness, good wear resistance and good thermal hardness. Its disadvantage is that it is brittle. It has higher usage strength, better impact resistance and shock resistance than YG6, but lower wear resistance and good tempering stability, which can reach 800-900°C. Without heat treatment, the internal and external hardness is uniform.[/prisna-wp-translate-show-hi

1 Suitable for high-speed cutting of large-volume production of cast iron, white cast iron, ductile iron, chromium, nickel stainless steel and other alloy materials.

2. The concave die used for stainless steel drawing dies, the recommended hardness value is 62-64HRC, and the tungsten carbide drawing dies for rods and tubes.

3. It can be used to process short-chip ferrous metals, non-ferrous metals and non-metallic materials, such as cast iron, aluminum alloy, copper alloy, plastic, hard bakelite, etc.

4 for tungsten carbide wire drawing mold

Post time: Jan-22-2024