Introduction of YG20C alloy:

YG20C is what kind of material?YG20C is optimized on the basis of YG20 alloy, which is synthesized by sintering the hard compounds of refractory metals and binder using the principle of powder metallurgy with a high-performance hard example. The alloy has high strength, high hardness, high elasticity mold and good wear resistance and impact toughness and electrical machinability. YG20C tungsten steel with excellent overall performance and is widely used in machinery manufacturing, metal processing, oil drilling, mining, cold pier molds and shield cutting tools and other fields.

YG20C alloy chemical composition %:

The chemical composition of the alloy is as follows:

C: 20%

Co:20%

WC:80%

YG20C tungsten steel physical and mechanical properties:

Bending strength Tensile strength Compressive strength Impact toughness Density WC Average grain size

≥1800MPa ≥2200MPa ≥3000MPa 5.1J/cm2 13.4-13.6g/cm3 1.8um

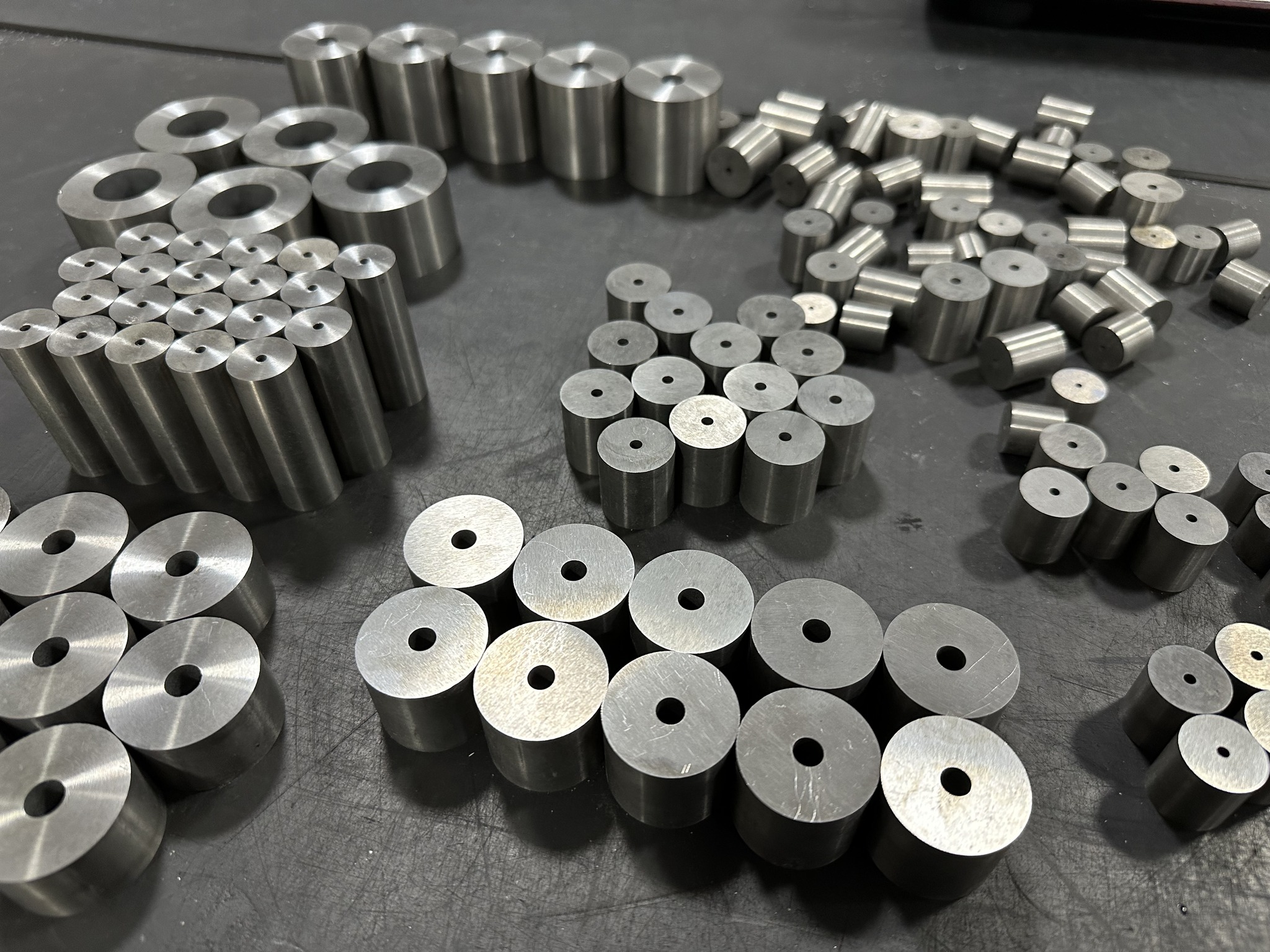

YG20C tungsten steel use

Suitable for making cold heading, cold punching and cold pressing molds for standard parts, bearings, tools and other industries.

Suitable for stamping molds of bullet head to cartridge case

Suitable for cold heading screws, nuts, cold punching steel balls, etc.

Suitable for aluminum alloy parts, steel parts and other cold extrusion die in the requirements of wear-resistant concave die.

YG20C gas permeable steel factory hardness and supply status

YG20C tungsten steel factory hardness 83-86HRA.

Post time: Jul-24-2023