Cold heading mold materials are an important part of manufacturing cold heading molds and are directly related to cold heading production.

product quality and service life. The cold heading mold is a key tool in the cold heading process and is used to

Metal materials are cold forged into parts of the desired shape. The selection of cold heading mold materials affects the use of the mold

It has an important impact on service life, production efficiency and product quality.

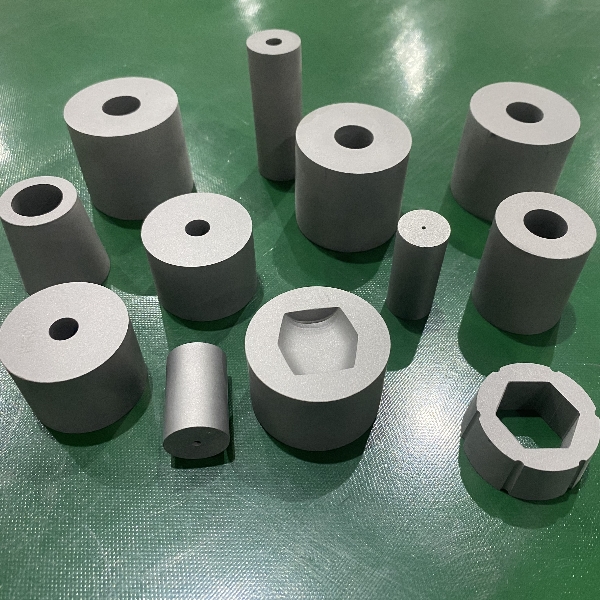

Cold heading mold materials need to have high hardness tungsten carbide die and wear resistance. During the cold heading process, metal materials

Under the action of pressure and friction, the material will cause greater wear and tear on the surface of the mold.

The material of this mold must be wear-resistant and able to maintain its durability after long-term use.

High hardness and precision. Common punch tools materials include alloy tool steel, high speed steel, hard

high-quality alloys, etc., which have high hardness and wear resistance and are suitable for manufacturing high-strength and

High-precision cold heading mold.

Cold heading mold materials need to have good thermal fatigue resistance. In the cold heading process, the mold

It will be subject to cyclic screw die loading and high temperature, and is prone to problems such as thermal fatigue cracks and deformation.

Therefore, cold heading mold materials need to have good thermal fatigue bolts die resistance and be able to operate at high temperatures and

Maintains good structural stability and strength under cyclic loading. Commonly used cold heading mold materials such as

High-speed steel and cemented carbide, etc., which have high thermal stability and thermal fatigue resistance,

Suitable for manufacturing high-temperature, high-strength cold heading molds.

Cold heading mold materials also need to have good toughness and impact resistance. In the cold heading process,

When the mold is subjected to cold heading force and impact force, problems such as plastic deformation and fracture are prone to occur.

Therefore, cold heading mold materials need to have good toughness and impact resistance and be able to withstand

Larger cold heading force and impact force without damage.

www.ihrcarbide.com

Post time: Mar-25-2024