1、Tungsten and cobalt carbide

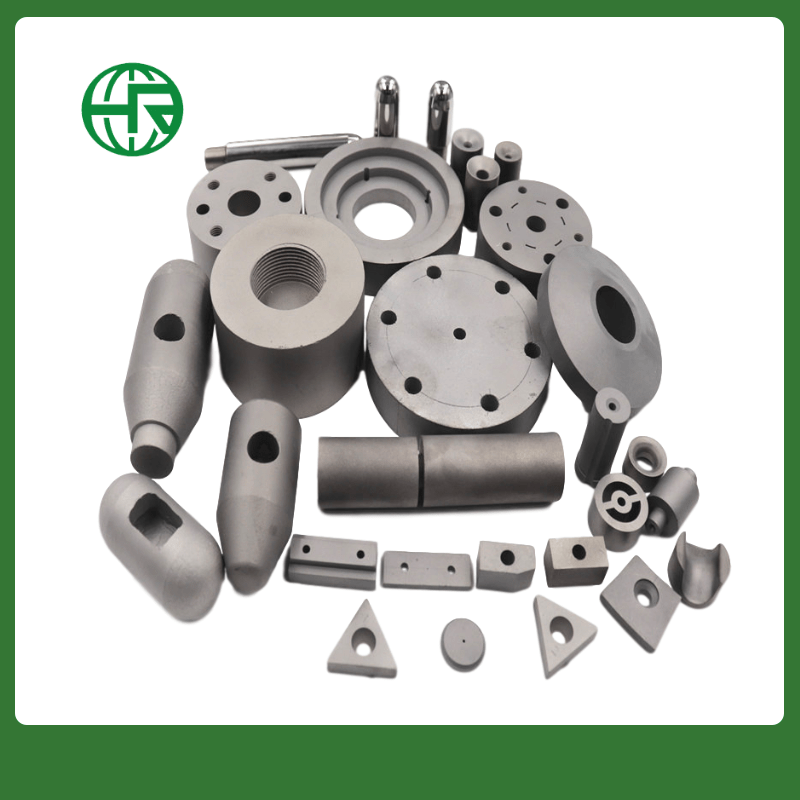

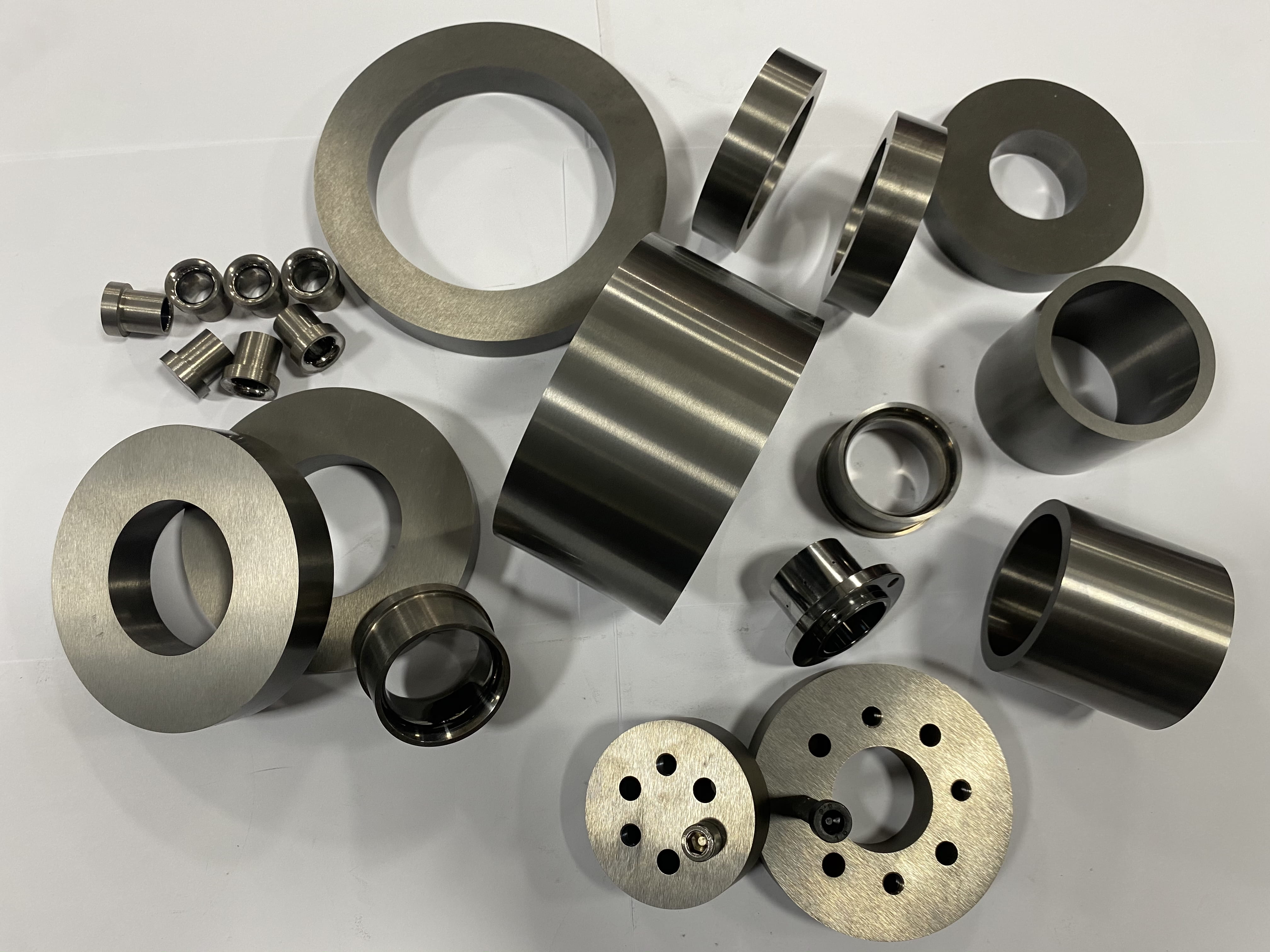

The grade consists of YG and the average percentage of cobalt content. Tungsten cobalt carbide can be used to cut cast iron, non-ferrous metals and non-metallic materials, and can also be used as tensile dies, cold punching dies, nozzles, rollers, top hammers, gauges, sharpening tools and other wear-resistant tools and mining tools.

2、Tungsten, titanium and cobalt cemented carbid e

e

The grade consists of YT and the average content of titanium carbide. Tungsten titanium cobalt carbide has high resistance to crescent pits wear ability, suitable for long cutting material tools.

3、Tungsten-titanium-tantalum (niobium) carbide

The grade consists of YW plus sequential number.

Cemented carbide has high hardness, strength, wear resistance and corrosion resistance, used for manufacturing cutting tools, cutting tools, cobalt tools and wear-resistant parts, widely used in military industry, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communication, construction and other fields.

There are many kinds of tungsten cobalt cemented carbide, which can be divided into 3 categories of low cobalt, medium cobalt and high cobalt alloy according to its composition; 4 categories of micro grain, fine grain, medium grain and coarse grain alloy according to its WC grain size, and 3 categories of tungsten cutting tools, mining tools and wear-resistant tools according to its usage.

The performance of tungsten cobalt cemented carbide is related to the alloy composition, organization and manufacturing process. The most important factors are: the composition and content of the bonding metal; the particle size and distribution of WC; the carbon content; the composition and content of additives, and various process factors affecting the alloy phase composition, WC grain size and densification.

Compared with tungsten cobalt carbide, the flexural strength of tungsten titanium cobalt carbide with the same cobalt content is lower and decreases with increasing TiC content.

Post time: Jun-14-2023