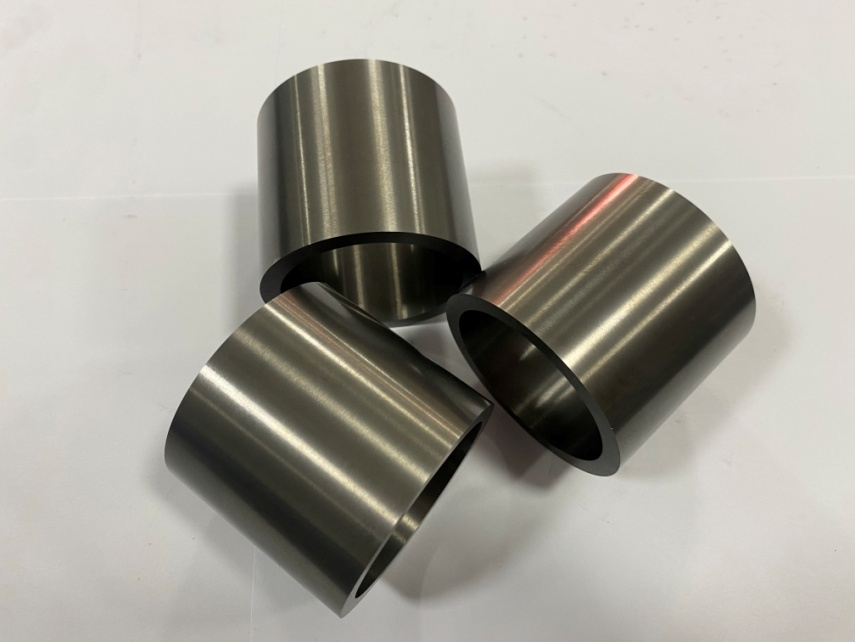

Tungsten Carbide Bushing bushings are mainly used for stamping aspects and drawing aspects. Carbide bushing is widely used as a tool material, such as turning tools, milling tools, planing tools, drills, boring tools, etc. It is used to cut cast iron, non-ferrous metals, plastics, chemical fibres, graphite, glass, stone and ordinary steel, and can also be used to cut heat-resistant steel, stainless steel, high manganese steel, tool steel and other difficult to machine materials. The cutting speed of the new cemented carbide bush tools is equal to hundreds of times that of carbon steel.

The main role of cemented carbide bushing is that they are a type of component that protects the equipment, using them can effectively reduce the wear between the punch or bearing and the equipment and achieve a guiding role. In stamping dies, tungsten carbide bushings are widely used because they are wear resistant, have a good finish and do not need to be replaced frequently, thus achieving higher usage rates for equipment and personnel.

Tungsten carbide bushings in the stretching, mainly some copper, stainless steel parts of the stretching, due to the use of too high frequency, easy to heat, resulting in wear bushings, so that the punch needle running position, the size of the product error, and the appearance of the product is bad.

With the increase of oil extraction, shallow surface oil reduced, in order to ensure the use of oil people gradually to large deep wells, large slope well development, but the difficulty of oil extraction gradually increased, so the oil extraction parts required to have good wear resistance, corrosion resistance or impact resistance, etc..

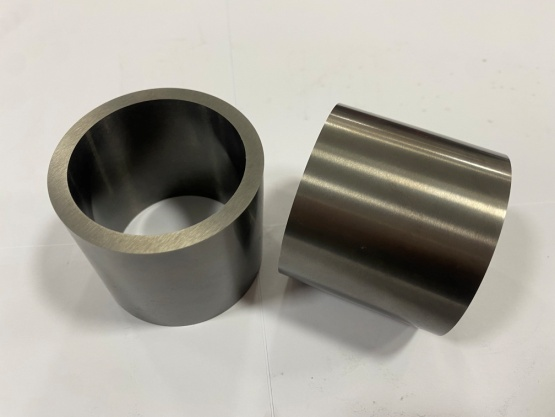

Tungsten carbide carbide bushings as petroleum machinery well in the wear-resistant parts, with high hardness, good wear resistance, high degree of finish performance, in modern society has been more and more widely used to meet the needs of daily use and special performance. Some companies use the spray welding process to improve the durability and service life of the carbide bushings.

After spray welding the hardness of the cemented carbide bushings can reach HRC60, better wear resistance, can meet the requirements of the petroleum machinery industry, but after spray welding the carbide bushings need to be turned in order to ensure the size requirements and accuracy requirements of the drawings.

Common tool materials include carbide tools, ceramic tools and cubic boron nitride tools, but carbide tools can be excluded from the hardness of carbide bushings. Ceramic tools are suitable for machining high hardness workpieces but only for finishing processes with small margins. Therefore, the most suitable tool material for machining carbide bushings is not the cubic boron nitride tool.

Post time: Feb-24-2023