The main production process of cemented carbide products is the sintering process, and sintering has a decisive influence on the performance of cemented carbide products, even if the press billets are the same, using different sintering processes has a different impact on the performance of sintered products.

Sintering of cemented carbide products results in bonding between the powder particles and the content of the bonded phase is a factor in determining the properties of the cemented carbide. Also increasing the cobalt content and increasing the WC grain helps to increase the toughness but also decreases the hardness and therefore the wear resistance of the substrate.

During the sintering process of cemented carbide products, the pressed billet undergoes a series of physicochemical changes, beginning with the evaporation or volatilization of water or organic matter, the elimination of adsorbed gases, the elimination of stresses, the reduction of oxides on the surface of powder particles; followed by diffusion between atoms, sticky flow and plastic flow, the increase of contact surfaces between particles, recrystallization, grain growth, etc.

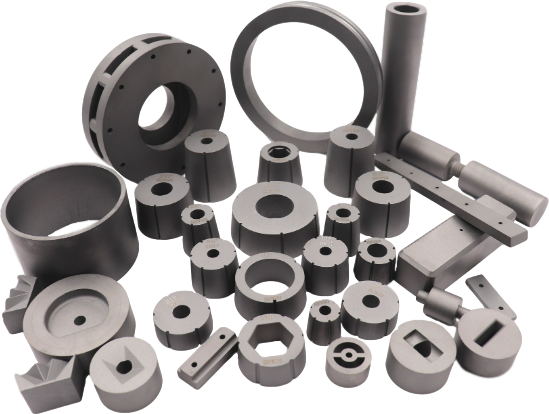

The cemented carbide products produced by Renqiu Hengrui Cemented Carbide Co., Ltd. adopt advanced technology, through the process of deep cooling treatment, overpressure sintering, isostatic pressing, special ingredients, spray granulation, etc. The whole process is according to the national cemented carbide standard specification, so its product quality is guaranteed.

Post time: Jun-20-2023