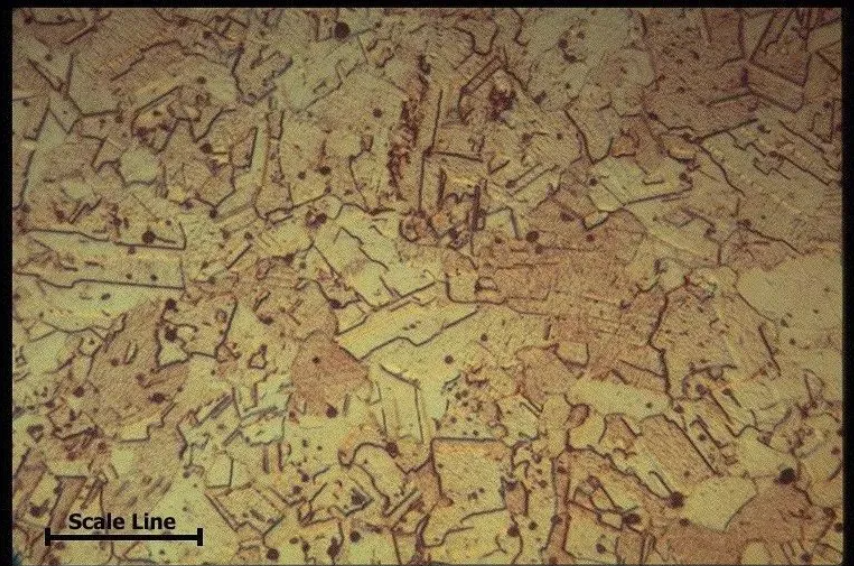

Tungsten carbide pores are generally caused by impurities in the blank block before sintering. Due to the uneven distribution of the pores in the sample, a few more fields should be observed. When detecting, you can observe one by one (from the edge of the sample section to the center). Select the most visual field with the most pores compared with the GB/ T 3489-1983 porosity standard picture. GB/T3489-1983 pore degree picture is divided into 11 levels, and its pores account for 0.1%, 0.2%, 0.4%, 0.6%, 0.8%, 1.0%, 1.2%, 1.4%,

Tungsten carbide blocks after polishing the sample are observed at 100 times, and the size is greater than or equal to 25 μm. The black hole with irregular shapes but clear edges is called dirt. It is the dust or other dirt of people in the mixture of tungsten carbide powder and the suppression process, and the shrinking holes left by shrinking after sintering. The total length of all dirt on the sample polishing surface is called dirt.

Post time: Jan-14-2024