Hot cracking defects: Carbide is prone to hot cracking at high temperatures. This is mainly because cobalt may react with carbides at high temperatures to form harmful phases, thereby reducing the toughness and reliability of the material

Porosity defects: Carbide contains pores. These defects are caused by the influence of gas during the preparation process. In addition, the density of cemented carbide itself is not high, which is also a reason for the porosity problem.

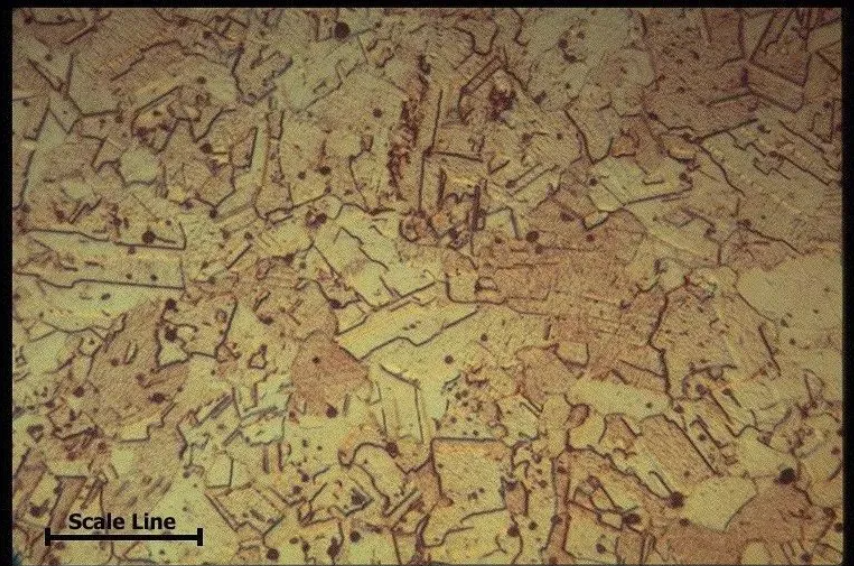

Grain boundary brittleness: At higher temperatures, brittle fracture may occur at the grain boundaries of cemented carbide, and this defect can seriously affect material properties.

Easy to fracture: Carbide has relatively low fracture toughness, and microcracks may appear even under low loads, causing the component to break.

Easy to break: Carbide also has insufficient fracture toughness and will easily break when subjected to large impacts or bending loads.

Not heat-resistant: The thermal stability of cemented carbide is poor. When the temperature exceeds 500°C, its organizational structure may change, thereby losing its original performance.

Poor toughness: The toughness of cemented carbide is weaker than other engineering materials and cannot withstand large impact forces.

Post time: Feb-20-2024