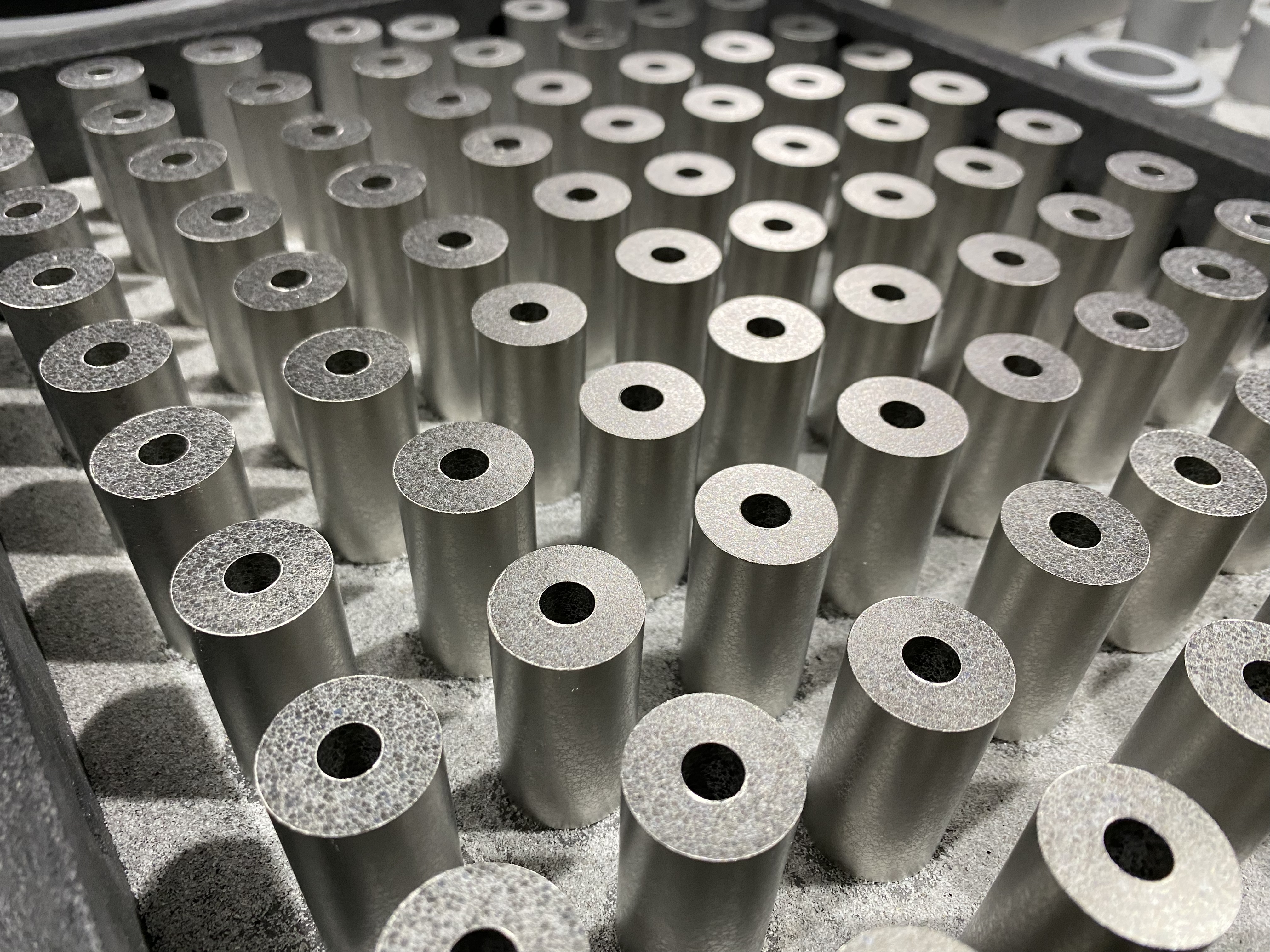

Cold heading dies are molds for cold heading processing, usually made of high-speed steel, alloy tool steel, hard alloy and other materials. Cold heading is a metal forming process in which the metal rod material is pressed and extruded through multiple dies to achieve a certain shape and size processing process. Cold heading dies are generally composed of multiple sections, and the shape and size of each section vary according to the required product. Common cold heading products include various threads, pin shafts and small diameter parts.

Tungsten carbide cold heading dies are generally manufactured by hot isostatic pressing sintering process. The sintering temperature mainly depends on the physical properties and chemical composition of tungsten carbide powder, as well as the sintering conditions used. Generally speaking, the sintering temperature of tungsten carbide cold heading die is above 1500°C, and the selection of specific temperature also needs to consider the design requirements and manufacturing process of the die. If the sintering temperature is too high, the mold structure will be deformed, and if the sintering temperature is too low, it will be difficult to obtain sufficient strength and wear resistance. Therefore, the selection of sintering temperature needs to consider various factors comprehensively to ensure the good performance and service life of tungsten carbide cold heading dies.

Post time: May-21-2023