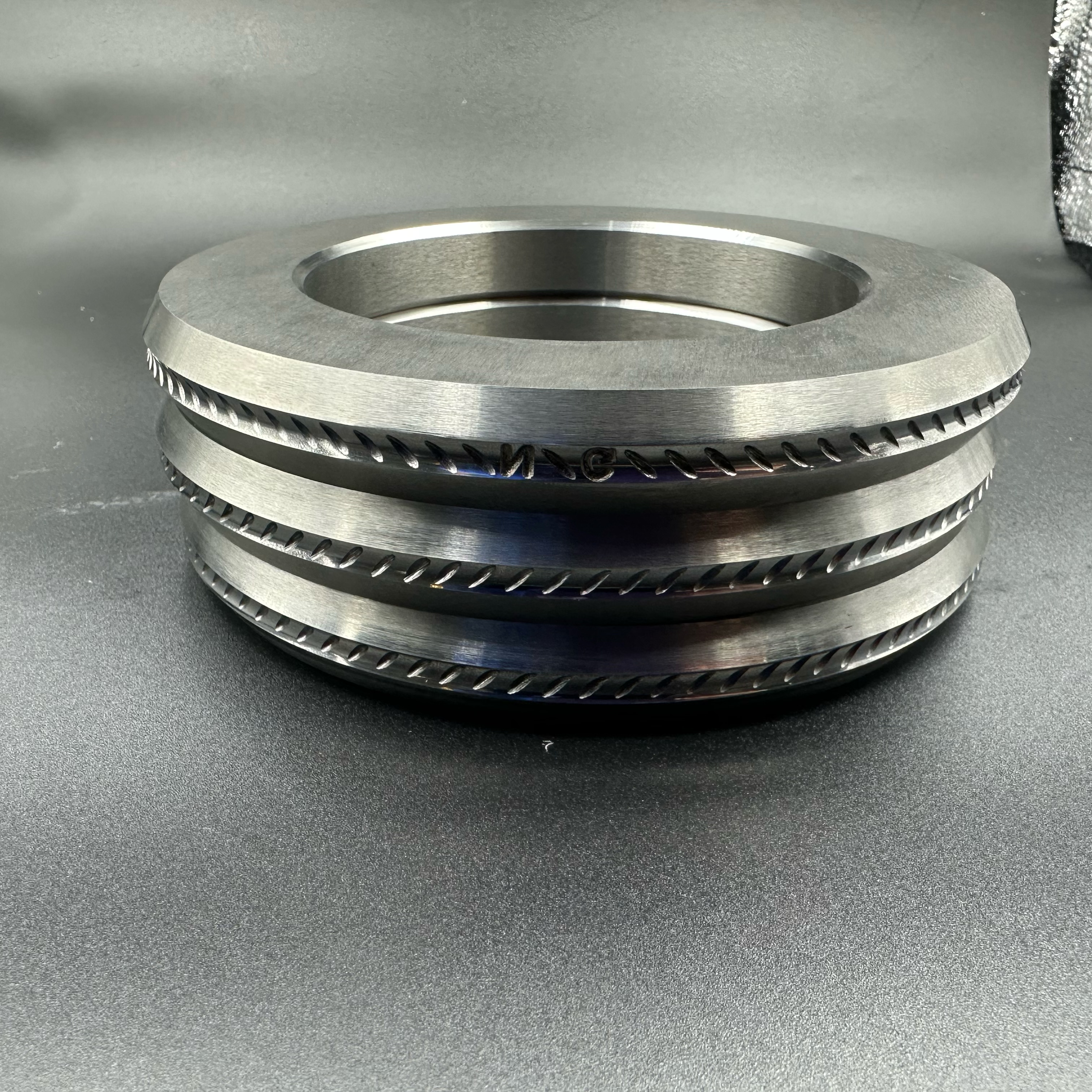

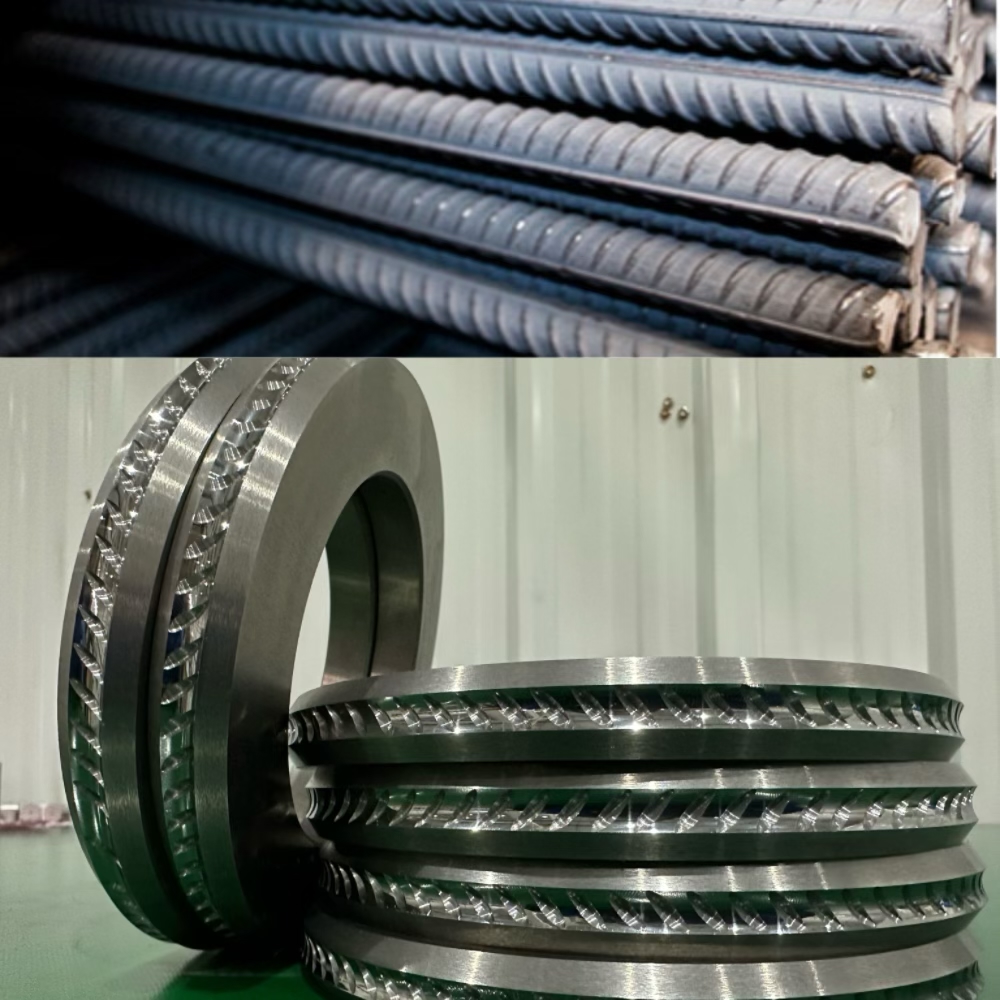

Carbide roller rings are tool materials with high hardness and high wear resistance composed of tungsten carbide and bonded metal. The carbide roller rings must give full play to their high wear resistance, long life and high wear resistance in high-speed wire rod rolling. The advantages of efficiency, when installing, we need to pay attention to the following things:

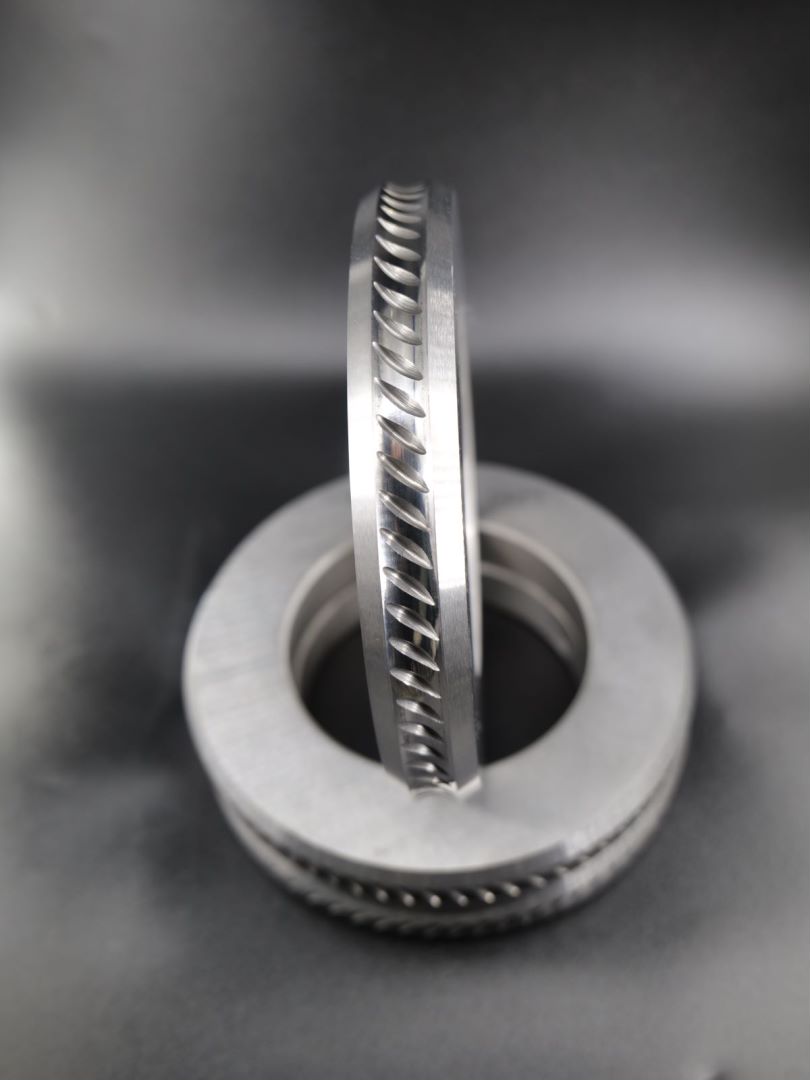

1. Matching rollers: The diameter difference of the same rollers on the same frame should be 0, not exceeding plus or minus 0.05mm

2. Before installing the carbide roller, the roller ring and taper sleeve should be kept at a constant temperature of 25-30 degrees Celsius. At the same time, pour hot water on the roller shaft, or run it idling for 20 minutes to preheat it.

3. The inserting of the carbide roller ring and the assembly on the machine are carried out strictly according to the accuracy required by the design process. The roller ring, the frame roller shaft and the taper sleeve must have a suitable fit and cannot be too tight or too loose.

4. Before using the machine, check whether the roller ring meets the requirements, and the assembly surfaces of the carbide roller ring, taper sleeve, and shaft must be carefully scrubbed clean. It is strictly forbidden to use a hammer or other hard object to knock the roller ring when using the machine, during transportation, and installation. It is strictly forbidden to collide with each other during the process to prevent damage to the roller rings.

Post time: Mar-24-2024