Let’s start with the processing equipment:

1, the inner groove, hole, internal and external threads and other processing equipment: with these characteristics of the shape, we generally want to use a special CNC machine tool – ceramic engraving and milling machine, this machine tool literally seems to be related to ceramics, in fact, this machine tool is also applicable to the processing of cemented carbide. Because when processing carbide, more dust will be generated, and the damage of these dusts to the machine tool is still more serious. The traditional CNC is difficult to resist these fine dusts, thus easily leading to the wear and tear of the screw as well as other parts. The ceramic engraving and milling machine can solve this phenomenon very well, because the ceramic engraving and milling machine has very perfect protection measures, which can well isolate the carbide powder from the precision components.

2、Processing equipment for planes and steps: When processing large planes and steps on top of carbide materials, it is best to use surface grinders, which have high processing accuracy and efficiency.

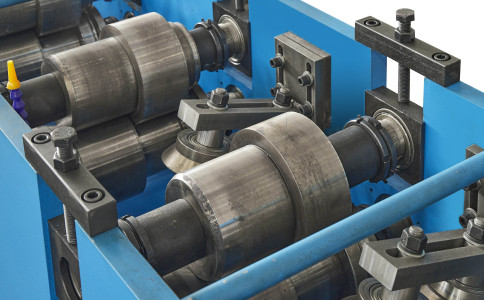

3、Processing equipment for external circle: external grinding machine, centerless grinding machine, etc. can be used when processing carbide external circle.

Machining methods of cemented carbide:

1、Machining of internal and external threads: The thread processing of cemented carbide should be processed by thread milling, not by tap directly.

2、Processing of internal groove: diamond grinding rod should be used, and the amount of undercutting is controlled by about 2-3 wires each time, which should be adjusted according to the advantages and disadvantages of diamond grinding rod.

3、Electrical discharge machining (in the wire, slow walking wire, fast walking wire processing)

4、Welding processing: copper welding, silver welding processing.

5、Grinding processing: centerless grinding, internal grinding, plane grinding, tool grinding processing, the grinding wheel used is generally diamond grinding wheel, depending on the process requirements to choose.

6、Laser processing: laser cutting and forming, punching, but the thickness of the cut is bound by the power of the laser machine

Post time: Jun-22-2023