Cemented carbide can be classified according to the cobalt content: low cobalt, medium cobalt, and high cobalt three. Low cobalt alloys usually have a cobalt content of 3%-8%, and are mainly used for cutting, drawing, general stamping dies, wear-resistant parts, etc.

Medium cobalt alloys with cobalt content of 10%-15% have good versatility and are suitable for impact stamping dies and special wear-resistant tools. High cobalt alloy with cobalt content greater than 15% is mainly used for cold heading dies, cold forging dies stamping dies with large impact loads, etc.

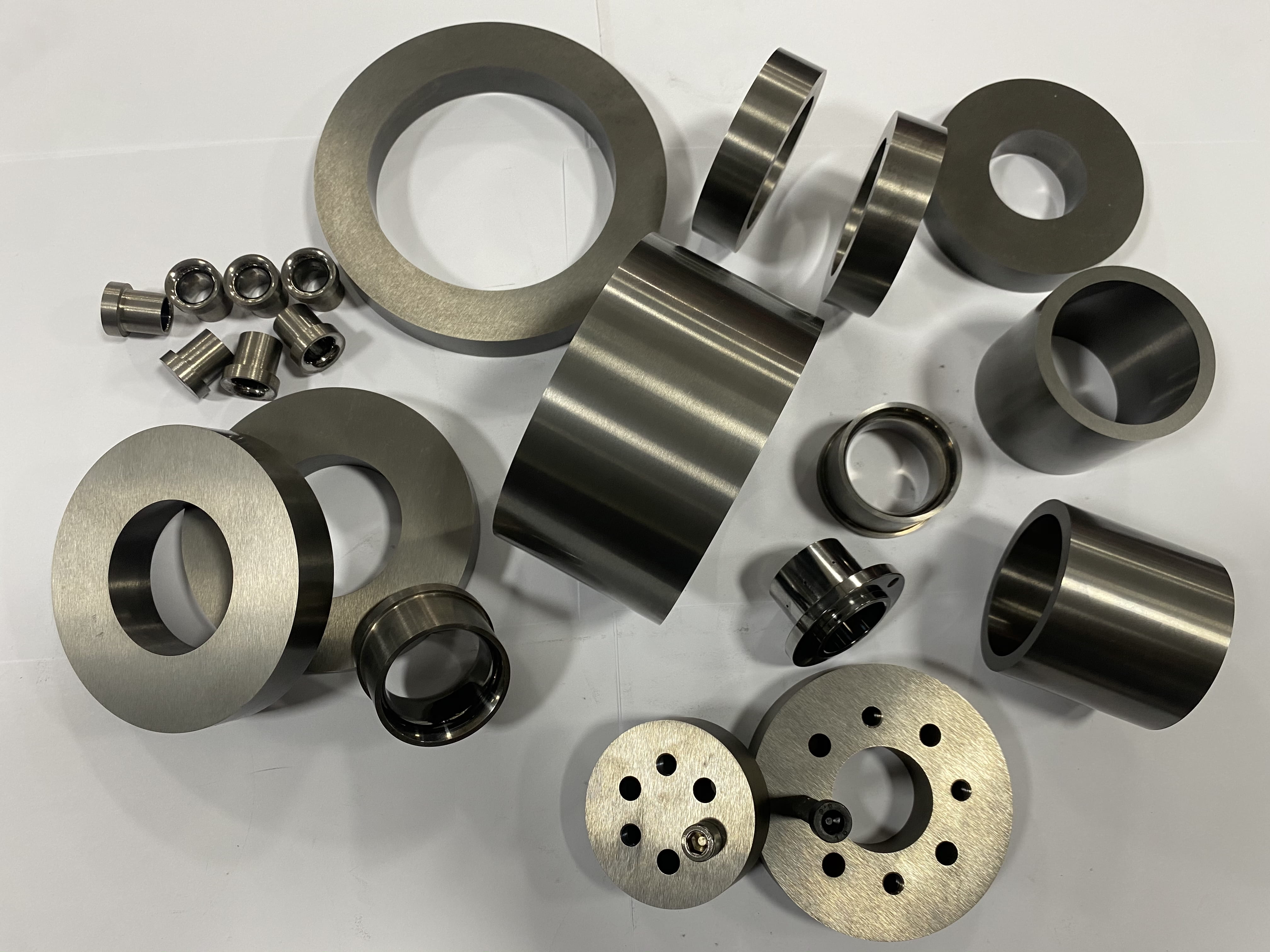

Cemented carbide has high hardness, high strength, good toughness, wear resistance, heat resistance, corrosion resistance and a series of excellent properties, widely used as tooling materials, such as turning tools, milling tools, planing tools, drill bits, boring tools, etc., for cutting cast iron, non-ferrous metals, plastics, chemical fibers, graphite, glass, stone and ordinary steel, can also be used to cut heat-resistant steel, stainless steel, high manganese steel, tool steel and other difficult-to-machine materials. In addition, cemented carbide can also be used to make rock drilling tools, extraction tools, drilling tools, measuring gauges, wear-resistant parts, metal abrasives, cylinder liners, precision bearings and nozzles, etc.

Post time: Jun-02-2023