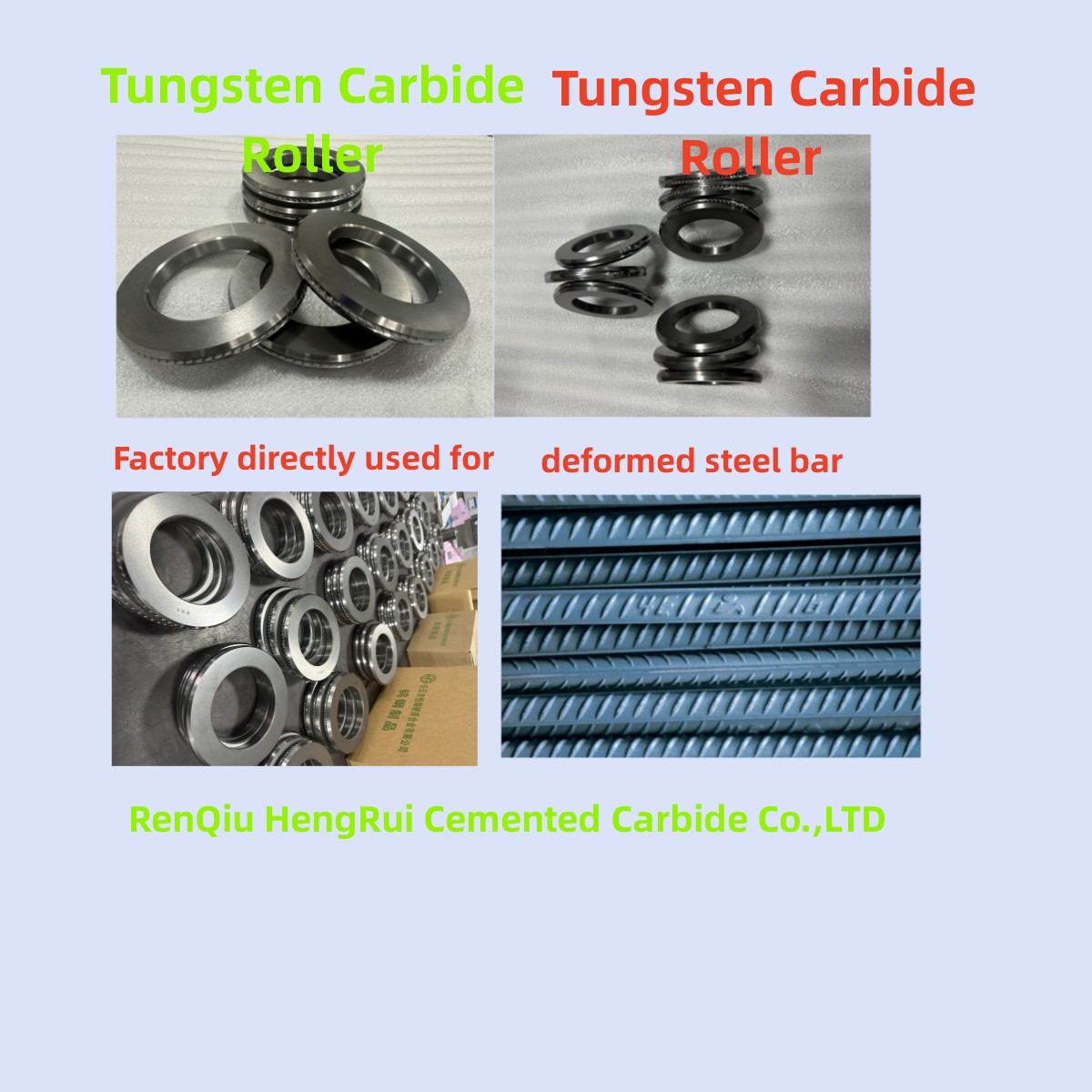

Deformed steel bars, also known as reinforcing bars or rebars, are produced by carefully controlling the manufacturing process of hot-rolled steel wire rod. Here’s a general production process: 1. Steel wire rod is produced through a hot-rolling process that compresses the steel at high temperatures. The steel is reduced in size to a diameter of about 5mm to 12mm depending on the required size of the rebar. 2. Once the wire rod is produced, it is then passed through a specialized rolling mill which applies pressure to the surface of the wire rod. The rolling process deforms the surface of the steel wire rod to create ribs and indentations that provide a better grip or adhesion to the concrete. 3. The deformed steel bars are then passed through a cooling system to properly temper and harden the steel and reduce brittleness. 4. The bars are then cut to the required length and bundled. 5. Finally, these bars are subjected to stringent quality checks and tests for strength, flexibility, and durability to ensure that they comply with international standards for reinforcement steel. The finished production tungsten carbide roller of deformed steel bars is used in construction projects to provide additional strength and stability to concrete structures, such as in bridges, buildings, and dams.

Post time: May-21-2023