Each step in the production process of tungsten carbide tooling is critical and directly affects the quality and performance of the carbide tooling after production. What is the production process of Cemented Carbide Moulds?

1: raw materials do spray drying: mixture preparation in a fully closed ring mirror using high-purity nitrogen protection, effectively reduce the preparation process mixture oxygenation may, and can effectively ensure the purity of the material, to prevent the material from dirtying.

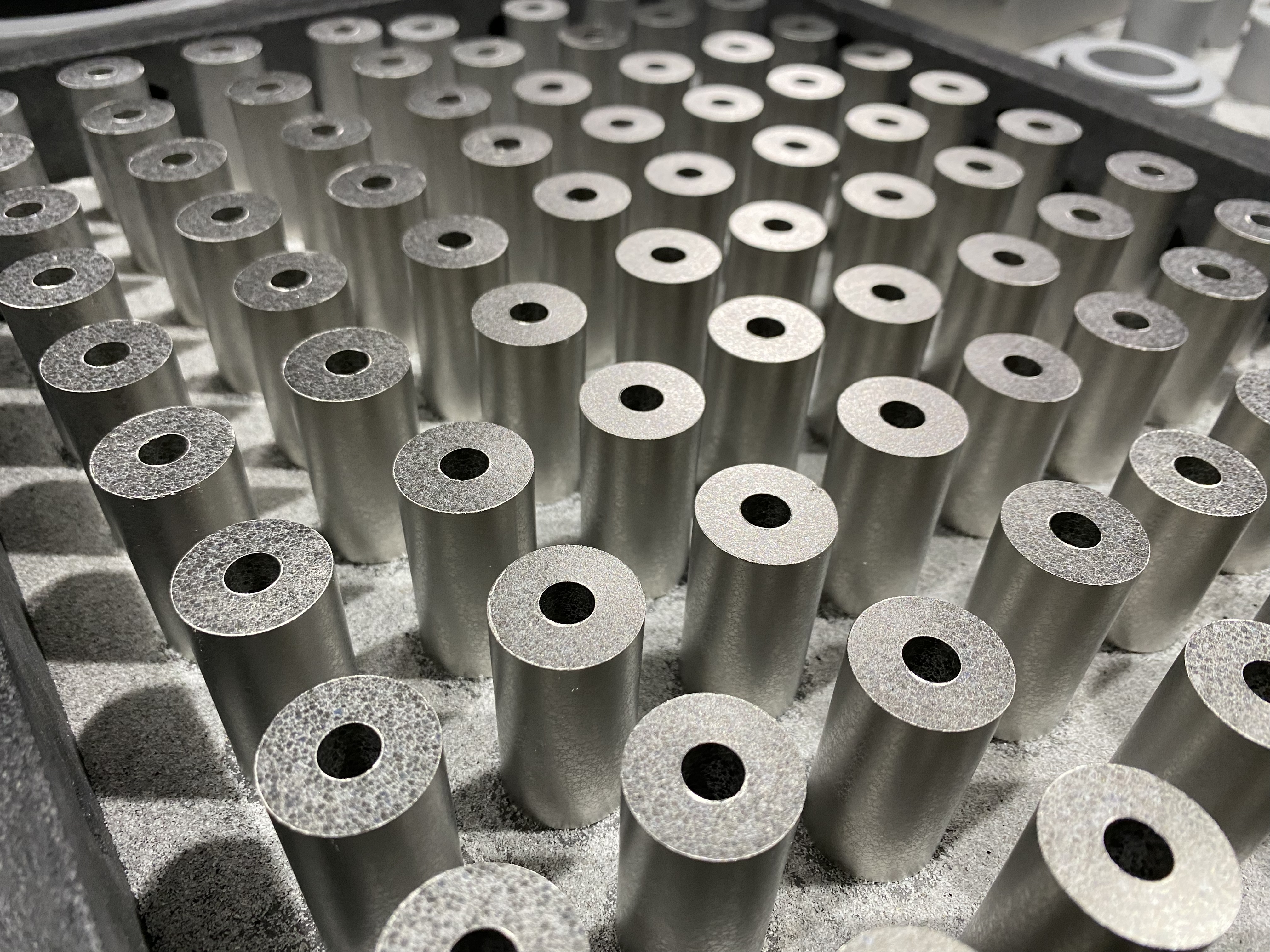

2: CIP (cold isostatic pressing): 3000Mpa isostatic press is used to effectively eliminate the production of pressing defects, providing a good guarantee for the pressing of uniform density of the blank.

3:SP low-pressure sintering: the maximum sintering pressure and can reach 100 kg, so that the internal voids of the alloy muscle can be effectively eliminated, so as to obtain well-densified high hardness, high strength cemented carbide mold. The advanced temperature control system can effectively reduce the possibility of quality fluctuation of the carbide mold.

4: Deep cooling treatment: effectively improve the microstructure of tungsten carbide carbide die, so that the internal stress of carbide die can be effectively eliminated.

5: Analysis and testing: National-level testing center, which can carry out perfect testing of all kinds of properties, and the adoption of ultrasonic flaw detection means to ensure the stable quality of cemented carbide moulds.

Post time: Jun-08-2023