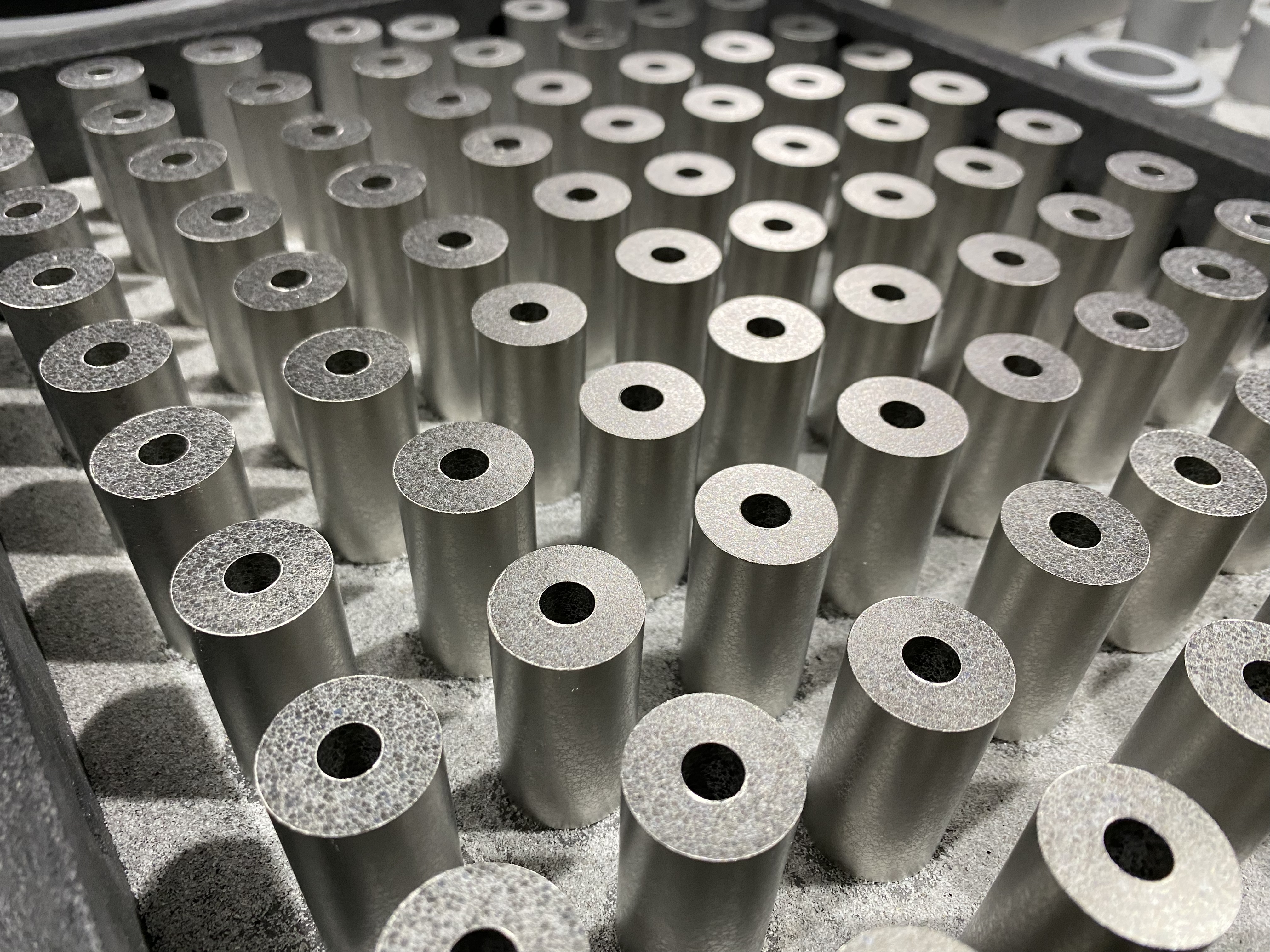

Cold heading die is a stamping die mounted on a press to punch, bend, stretch, etc..

The cold heading die is subjected to severe stamping load and its concave die surface is subjected to high compressive stress. The die material is required to have high strength, toughness and wear resistance. After heat treatment, the surface of our tungsten carbide cold heading die must have high hardness and the heart must have good toughness, so that the surface has a certain compressive stress that can offset the stress borne in the cold heading process. It can make the die last longer.

In order to increase the performance of tungsten carbide cold heading products, all of our carbide cold heading die blanks are quenched and tempered after the sintering process. The quenching and tempering process is to heat the sintered alloy blanks in a high pressure gas quenching furnace to over 1300 degrees and then rapidly and sharply cool them and then heat them again for tempering. In this process, as the temperature rises, the solubility of tungsten carbide in cobalt increases, and the temperature cools sharply so that the tungsten carbide dissolved in the cobalt phase does not precipitate out in time, and some or all of it is retained. Then tempered to eliminate the quenching internal hardness. By controlling the decomposition and dispersion of saturated solid solution, the metallurgical composition and organization of the alloy are changed, and the performance is improved.

Post time: May-30-2023