The density of tungsten carbide impacts several of its properties. Tungsten carbide has a high density, typically around 15 g/cm3, which gives it its excellent strength and wear resistance. The higher the density, the stronger and more resistant to wear the material will be.

This makes it an ideal material for use in heavy-duty applications in industries such as mining, metalworking, and oil drilling. The density of tungsten carbide also affects its thermal and electrical conductivity. Despite being a good thermal conductor, tungsten carbide’s high density can limit its thermal conductivity, which can sometimes lead to thermal cracking and deformation under extreme conditions.

Additionally, the density can affect the material’s electrical resistivity, making it suitable for electrical discharge machining. Another aspect influenced by the density of tungsten carbide is its toughness. Generally, the denser the tungsten carbide, the more brittle it becomes, making it more prone to cracking under impact or bending stresses. However, by combining tungsten carbide with other materials and manufacturing techniques such as sintering, manufacturers can enhance its toughness and prevent premature failure.

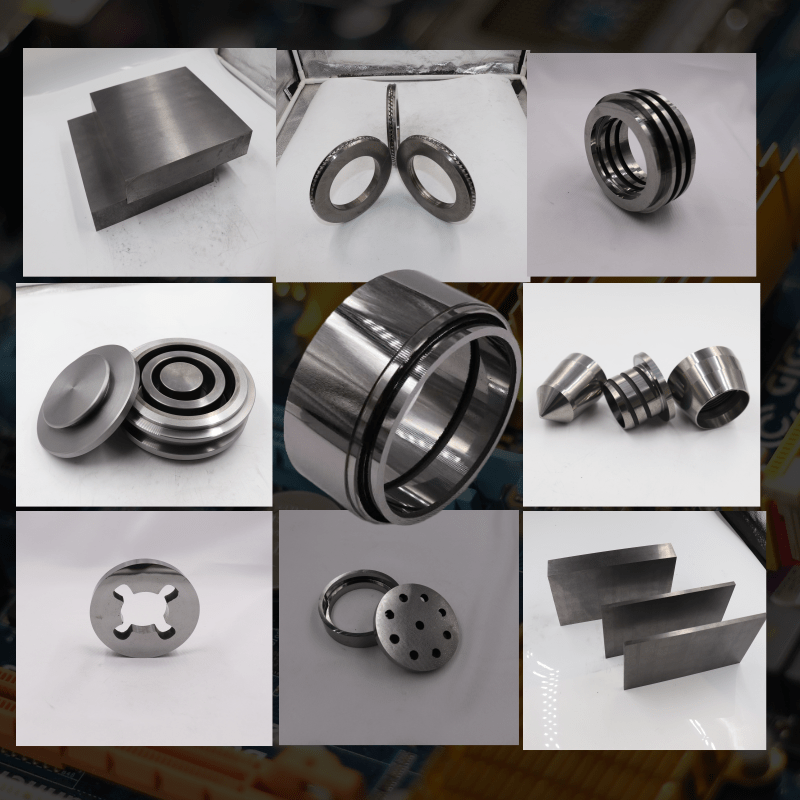

In conclusion, the density of tungsten carbide is a critical factor that determines many of its properties, including strength, wear resistance, thermal and electrical conductivity, and toughness. Therefore, manufacturers must control the density during fabrication, using high-quality raw materials, and employing optimized manufacturing techniques to produce consistent, durable tungsten carbide products.

Post time: Apr-22-2023