Although both tungsten alloy and cemented carbide are a kind of alloy product of transition metal tungsten, both can be used in aerospace and aviation navigation and other fields, but due to the difference of added elements, composition ratio and production process, the performance and usage of both of them also have big difference.

I. Definition

Tungsten alloy, also known as high specific gravity alloy, is an alloy with tungsten powder as the main raw material and nickel, iron, copper and other elements as auxiliary materials. The tungsten content is generally between 85% and 99%.

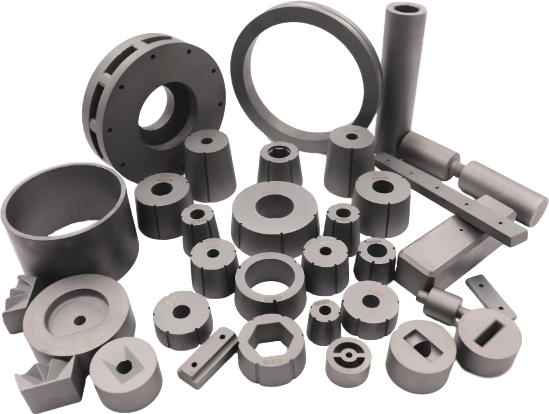

Cemented carbide, also known as tungsten steel, that is, is an alloy with refractory metal carbide such as tungsten carbide as the main ingredient and cobalt, nickel, molybdenum and other elements as the binder. The binder content is generally between 10% and 20%.

Second, the performance

High specific gravity alloy has a high melting point, density, strength and hardness, better plasticity, heat resistance, corrosion resistance,, impact resistance, oxidation resistance and shielding effect.

Tungsten steel also has similar properties to tungsten alloys, although its thermal hardness and wear resistance advantages are extremely obvious, mainly in the fact that it remains basically unchanged at 500°C and still has high hardness at 1000°C. However, its brittleness is very high, so it carries out cutting processing.

Third, the production process

Preparation steps of tungsten alloy: 1) material preparation: tungsten compounds such as ammonium tungstate, auxiliary materials such as nickel, iron, copper and other elements or compounds; 2) powder making: there are spray drying method and mechanical alloying method; 3) forming: after mixing tungsten powder with forming agent, extrusion is injected into the forming machine, then complex-shaped parts can be prepared; 4) sintering: after sintering treatment, the organization of the alloy is more uniform and the comprehensive performance higher overall performance.

Steps for preparation of cemented carbide: 1) Remove the surface impurities of tungsten carbide particles and cobalt grains; 2) Crush the above materials and mix them in the mixer, then grind them to obtain alloy powder; 3) Extrude the alloy powder into the extrusion die to obtain cemented carbide precursors, then mix them with liquid and add binder to make metal powder slurry; 4) Make the slurry into powder by spray granulator, then sinter and heat treat. then sintered and heat treated.

Post time: Jun-02-2023