China’s domestic consumption of tungsten has remained roughly stable at about 10,000 tons/year. According to reports, the consumption of tungsten in China was 9,200 tons, 9,400 tons and 9,500 tons in 1994-1996, and the consumption of tungsten in China is predicted to be 11,500 tons in 2000. Since the 1980s, the consumption structure of tungsten in China has been quietly changing. Statistics show that from 1980 to 1985, the consumption structure of tungsten for steelmaking accounted for 61% of the total consumption, accounting for the largest proportion;? From 1986 to 1990, the proportion of tungsten used in steelmaking decreased to 48%, while the proportion of tungsten used in cemented carbide increased to 28%. From 1991 to 1995, as the output of cemented carbide soared, the proportion of tungsten used in cemented carbide exceeded that of tungsten used in steelmaking, approaching 50% of the total domestic tungsten consumption, while the proportion of tungsten used in steelmaking dropped to about 40%.

It is obvious that the change of tungsten consumption structure in China is directly related to the production of cemented carbide. So, what is the trend of China’s cemented carbide production?The current trend of carbide production in China.

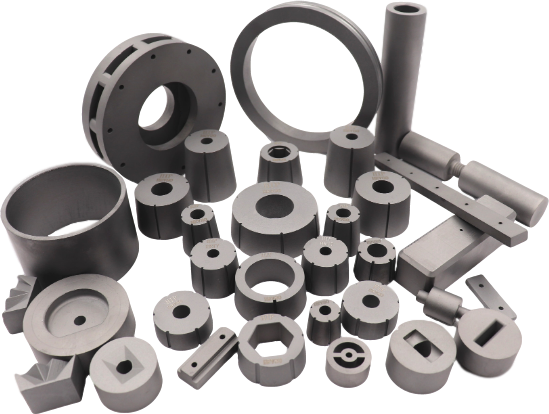

China’s cemented carbide industry began in the mid-1950s, and although the industrial system was formed about thirty years later than in the developed countries of the East and West, the speed of its development and the scale of its production were remarkable to the world. Especially in the 1990s, under the reform and opening up and market-oriented economy, the output of cemented carbide has been soaring high. At present, there are 150 cemented carbide manufacturers in China, with a total production capacity of 9,000-10,000 tons/year. The total annual production is about 7000-7500 tons, accounting for 21% of the world’s total annual production, which is more than the United States, Sweden, CIS and other countries with more advanced cemented carbide industrial system in early production and the world’s first. During the 8th Five-Year Plan period, the average annual production of cemented carbide in China was 6528 tons (the highest annual production was 7540 tons in 1994), and the average annual consumption was 5894 tons (the highest annual consumption was 6620 tons). According to the experts’ prediction, during the Ninth Five-Year Plan period, the average annual production of cemented carbide in China will increase by 6%, i.e., the average annual production will reach 6976 tons. Some experts use linear correlation equation to link the steel and cemented carbide production in China during the Ninth Five-Year Plan. The mathematical simulation was carried out to calculate the two indicators of GDP.

Third, the recycling and utilization of waste and residual carbide as a way to supplement the shortage of natural resources

Natural resources are limited, and the alarm bell of losing the advantage of tungsten resources has been echoing in our ears. In the face of this perilous situation, experts have formulated many countermeasures and remedial measures. Among them, the method of recycling and utilizing scrap residual tungsten carbide has proved to be a mature, effective and practical program. It is an effective way to reduce the cost of carbide production during the period of abundant natural raw tungsten, and an important aspect to make up for the lack of resources in the present and future when natural raw tungsten is becoming depleted. The degree of comprehensive utilization of recycled resources is one of the important signs of technological progress and economic development of a country and an enterprise. In fact, the developed countries in the East and West have already included the recycling and utilization of waste residual alloy in the normal production. At present, their recycling and utilization of scrap residual cemented carbide has reached 30-40% of the total annual production. China’s annual consumption of tungsten metal is about 10,000 tons, if it can reach 40% of the recycling, its economic benefits and resource replenishment effect will be very considerable. Take cemented carbide as an example, the total output of cemented carbide in China in 1994 was 7540 tons, according to the calculation of 40% recovery, not only can we recover nearly 3000 tons of tungsten metal, but also nearly 240 tons of cobalt metal. According to the calculation of consuming 2 tons of tungsten concentrate for every 1 ton of cemented carbide produced, the consumption of tungsten concentrate can be reduced by nearly 6000 tons. This will undoubtedly play a huge role in alleviating the shortage of resources.The basic situation of recycling and utilization of scrap carbide in China at presentThe scrap carbide residue we refer to here includes two parts: one is the unqualified products in the production process; the other is the used scrap carbide tools (blades, brazing heads, molds, etc.).

According to incomplete statistics, the total amount of residual carbide generated in China is about 3500 tons per year.According to foreign carbide manufacturers, among the used scrap carbide tools, generally speaking, 12-25% of the scrap welding inserts can be recycled; 65-70% of the scrap carbide dies (punching dies, pressing dies, drawing dies, etc.) can be recycled; 95-97% of the scrap machine clamping inserts can be recycled.

China started to recycle and utilize scrap carbide relatively late. In 1983, the recycling volume was only 300 tons, accounting for 8% of the output in that year; in 1985, it increased to more than 400 tons, accounting for 10% of the output in that year. accounting for 10% of the production in that year. In the nineties, the recycling work had a greater development. Now there are more than 150 cemented carbide manufacturers in the country, not only nearly 60 small and medium-sized factories have tungsten raw materials basically from recycled resources, that is, with the scale of Zhuzhou Cemented Carbide Factory and Zigong Cemented Carbide Limited Liability Company (formerly Zigong Cemented Carbide Factory) also opened up the production line of recycled waste residual cemented carbide. At present, the national recycling volume is above 1500 tons, which accounts for about 20% or more of the total output of cemented carbide in China and is close to the level of Japan. The process technology of recycling scrap residual cemented carbide is relatively complete,? s process of zinc melting method, electric melting method and mechanical crushing method is accurately mastered. The recycled recycled tungsten carbide powder (WC) and cobalt powder (Co), which are of excellent quality, can be used for manufacturing carbide, artificial diamond, metal industrial materials and other products. There are quite a few regions where the recycling and reclamation work is more active, among which are: Zhuzhou and Changsha in Hunan; Zigong in Sichuan; Qinghe in Hebei Province; Jinan in Shandong Province; Mudanjiang in Heilongjiang Province, etc. Cemented carbide manufacturers in these areas have achieved success in recycling and utilizing scrap residual cemented carbide.

词典

Post time: May-02-2023