Quenching and tempering is a heat treatment process used to improve the s of metals.Quenching is the heating of a metal above its critical point, followed by rapid cooling, so that it solidifies rapidly into a solid state. This can make the internal crystal structure of the metal tight, increase the hardness, and may also appear brittle. To compensate for its brittleness, tempering is required. Tempering is to reheat the quenched metal to a certain temperature, keep it for a period of time, and then let it cool naturally. This process relieves the stress produced during quenching, making it less hard, while maintaining the toughness and plasticity of the metal. Therefore, quenching and tempering is a very commonly used metal processing technology, which is widely used in machining, automobile manufacturing and tungsten carbide dies.

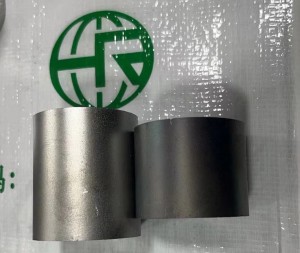

Cold heading die is a processing method that uses external force to change the volume or shape of the metal using a die to obtain the desired part or blank. Many fasteners, screws and nuts are made by cold heading wearing parts die forming method. Since cold heading dies work under wear-resistant conditions of impact or strong impact, carbide is required to have good impact toughness, fracture toughness, fatigue strength, bending strength and good wear resistance. In order to increase the performance of cold heading products, all of our carbide cold heading die blanks are quenched and tempered after sintering and forming. The quenching and tempering process is to heat the sintered alloy blanks in a high-pressure gas quenching furnace to over 1300 degrees and then rapidly and sharply cool them and then heat them again for tempering. In this process, as the temperature rises, the solubility of tungsten carbide in cobalt increases, and the temperature cools sharply so that the tungsten carbide dissolved in the cobalt phase does not precipitate out in time, and some or all of it is retained. Then tempered to eliminate the quenching internal hardness. By controlling the decomposition and dispersion of saturated solid solution, the metallurgical composition and organization of the alloy are changed, and the performance is improved. Now let’s see what is the difference between the quenched and tempered alloy: 1, appearance: quenched and tempered alloy due to high-temperature acute cooling and then high-temperature treatment from the original gray, gray-white into a dark gray, black or colored spots. 2, the use of performance: reasonable quenching and tempering alloy properties are improved, such as flexural strength increased by 15%, impact toughness increased by 50%, fracture toughness increased by 20%, the largest increase is the fatigue strength up to 10 times more.

Thus, the service life of the product can be improved. Quality is the responsibility, quality is the life of the enterprise, Renqiu City Hengrui carbide uphold the principle of not forgetting the original intention to create a future with you!

Post time: Apr-28-2023