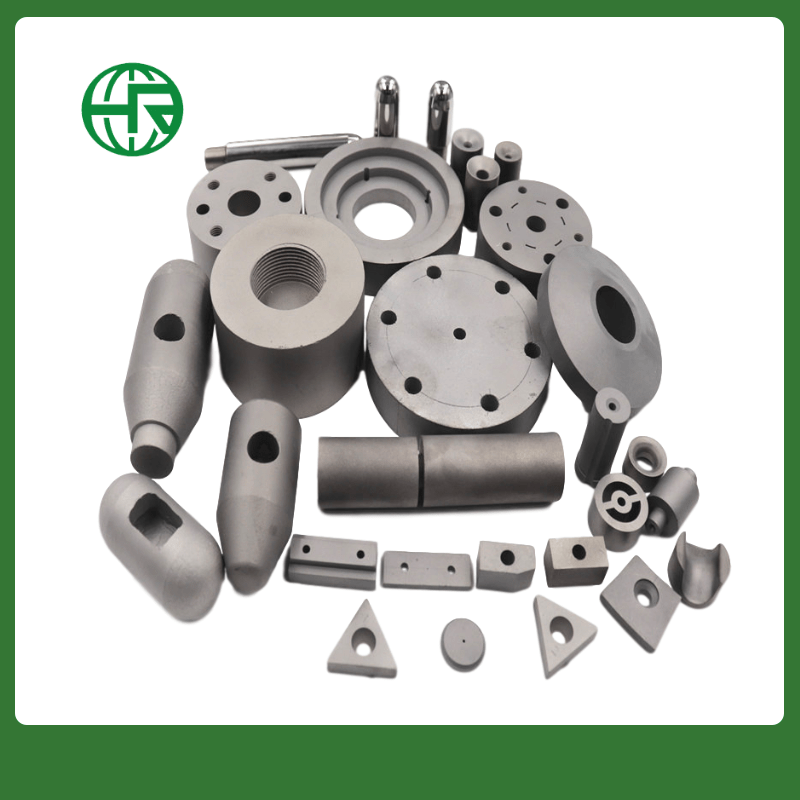

Cemented carbide mold is the life of steel cemented carbide die types introductionmold more than ten times or even dozens of times, cemented carbide mold only high hardness, high strength, corrosion resistance, high temperature resistance and small expansion coefficient, generally are used tungsten cobalt cemented carbide.

Cemented carbide dies have a series of excellent properties such as high hardness, wear resistance, better strength and toughness, heat resistance, corrosion resistance, etc. Especially its high hardness and wear resistance, even at a temperature of 500 ℃ also basically remain unchanged, at 1000 ℃ still have a very high hardness.

Cemented carbide dies can be divided into four categories according to their uses:

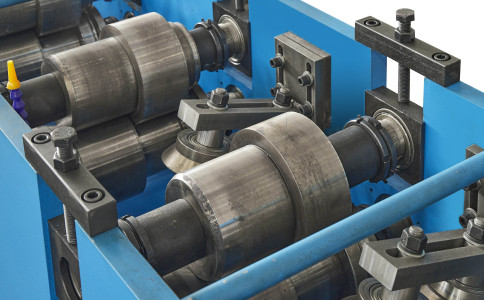

One category is cemented carbide wire drawing dies, which account for the vast majority of cemented carbide dies. At present, the main grades of wire drawing dies in China are YG8, YG6, YG3, followed by YG15, YG6X, YG3X, the development of some new grades, such as the new grade YL for high-speed wire drawing, and the introduction of wire drawing die grades from abroad CS05 (YLO.5), CG20 (YL20), CG40 (YL30); K10, ZK20/ZK30.

The second type of carbide die is cold heading cold punching die, shaping die, the main grades are YC20C, YG20, YG15, CT35, and YJT30 and MO15.

The third type of carbide dies is non-magnetic alloy dies for magnetic material production, such as YSN series of YSN (including 20, 25, 30, 35, 40) and steel junction non-magnetic die grade TMF.

The fourth type of carbide dies is hot work dies, there is no standard grade for this type of alloy at the moment, and the market needs are increasing.

Post time: Jun-14-2023