Due to the difference in hardness and wear resistance, YG15 is generally used in the manufacture of cutting tools, tungsten carbide rollers and other tools that require higher wear resistance, such as cutting tools, impact tools, etc.

Due to its ultra-high hardness, YG20 is generally used to make tools that require higher strength and greater wear resistance, such as mining tools, oil field drill bits, etc.

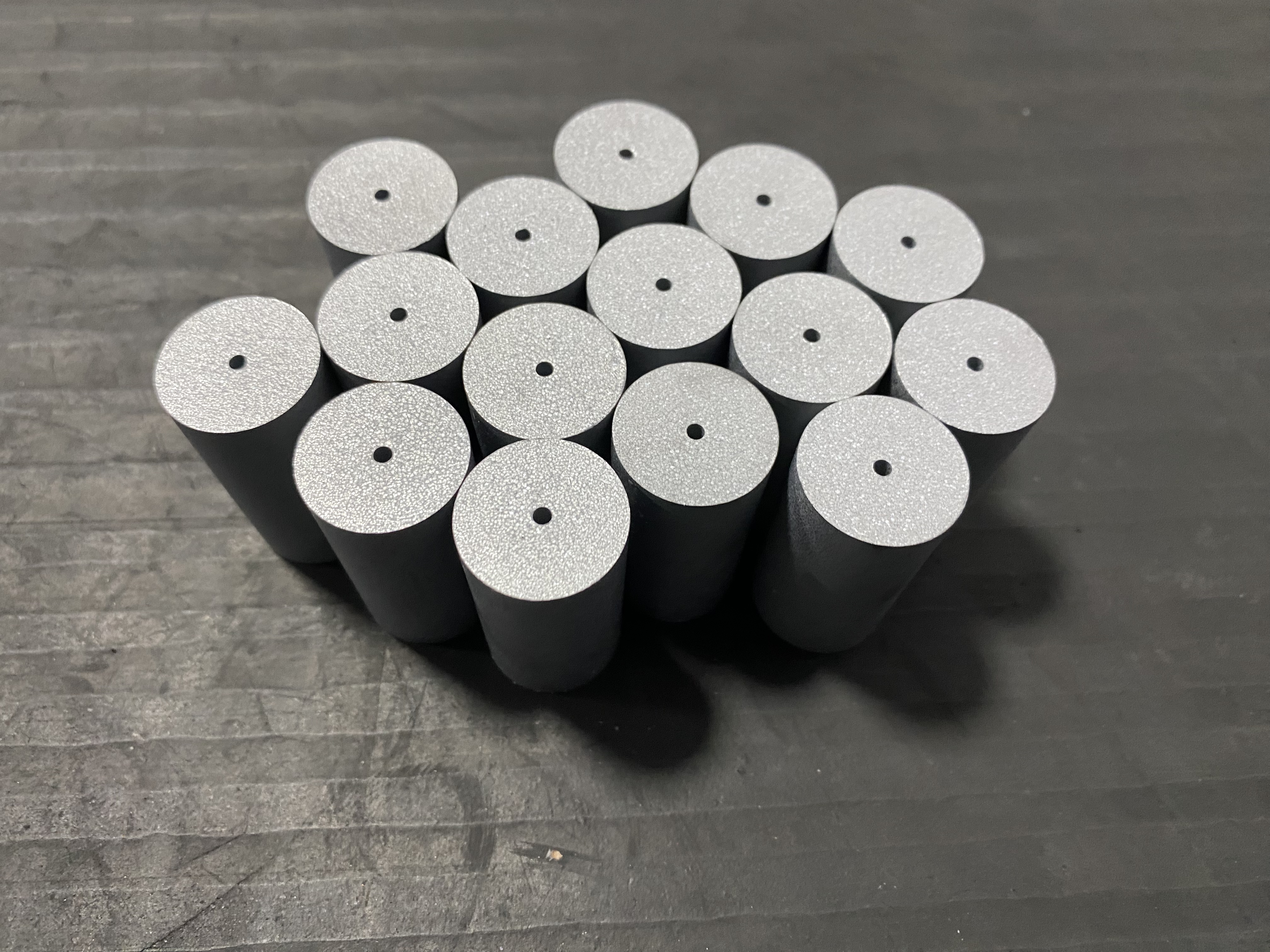

The main components of YG15 are tungsten carbide and cobalt, which are made through powder metallurgy process and have good strength and toughness.

YG20 has a similar composition, but contains less cobalt, making it harder. It is also made through powder metallurgy process, and the manufacturing process is more refined compared to YG15.

YG15 and YG20 are two common carbide materials. They have obvious differences in hardness and wear resistance. YG15 is suitable for tool manufacturing that requires higher wear resistance, while YG20 is suitable for tool manufacturing that requires ultra-high hardness and wear resistance. their ingredients

and manufacturing processes are also different, these factors jointly determine their application in the industrial field.

Post time: Jan-20-2024