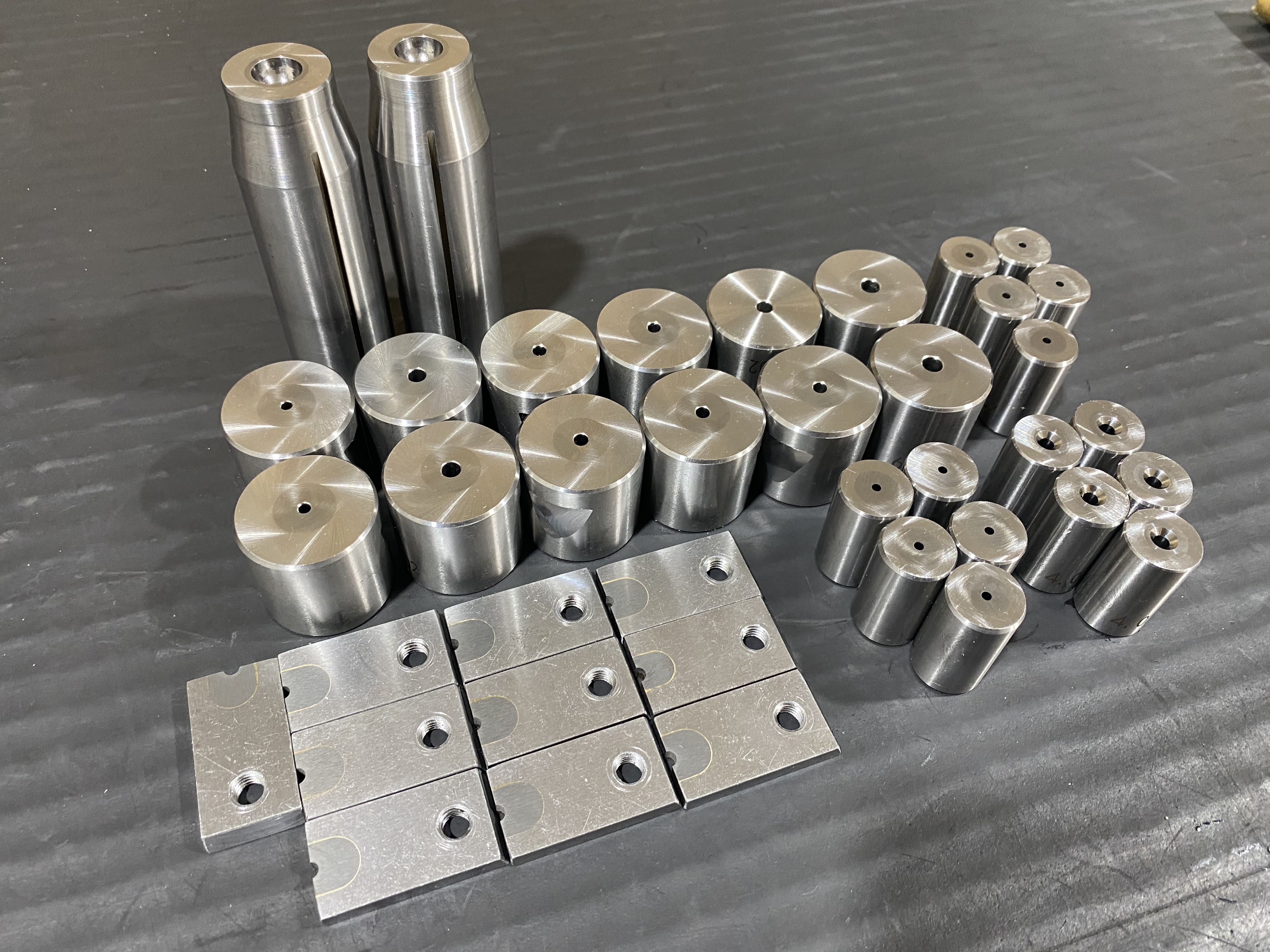

Cemented carbide has a wide range of applications in cold heading machines. The following are some major application areas: 1. Cold heading dies: Cemented carbide is widely used in the manufacture of cold heading machine dies, including dies and punches. Cemented carbide has high hardness, excellent wear resistance and corrosion resistance, and can withstand high-intensity deformation and friction, thereby ensuring long-term stable use of the mold. 2. Cold heading tools: Cemented carbide materials are also used to manufacture cold heading machine tools, such as cutting tools, cutting tools, etc. Carbide cutting tools have extremely high hardness and wear resistance, and can maintain cutting performance and long service life under high-speed and high-load conditions. 3. Cold heading process tools: Cemented carbide is also used in cold heading process tools, such as fixtures, positioning pins, positioning sleeves, etc. These tools need to have high hardness, good dimensional stability and wear resistance to ensure the precision and quality of cold heading. 4. Cold heading auxiliary materials: Cemented carbide can be used as auxiliary materials in the cold heading process, such as coolants, lubricants, etc. Cemented carbide can provide good heat dissipation and corrosion resistance, and can also improve friction and wear problems during cold heading, and improve processing efficiency and quality. In general, the application of cemented carbide in cold heading machines makes cold heading more efficient, accurate and reliable. Efficient production and high-quality processing of parts such as fasteners can be achieved by using molds, cutting tools and process tools of cemented carbide.

Post time: Jun-23-2023