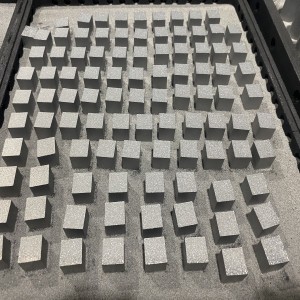

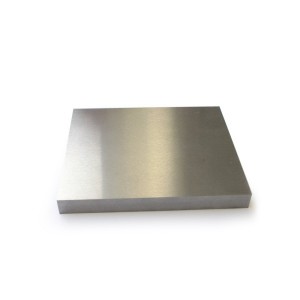

Chinese manufacturer WC and Co Tungsten carbide blanks Tungsten carbide plates

Carbide plate is also known as carbide plate and carbide sheet. It is one of the many materials of cemented carbide. It is named after its short plate (or square) shape.

Cemented carbide plates are mainly made of metal WC tungsten carbide powder and C0 cobalt mixed using metallurgical methods through powdering, ball milling, pressing, and low-pressure sintering. The product body has good compactness, no holes, no blisters, and high dimensional precision (blank tolerance It is controlled at +2.2~±2.2, and the fine blank is controlled at ±0.01). The processing margin is small, which can effectively improve your production efficiency and significantly reduce processing costs.

Commonly used metal carbides are tungsten carbide, titanium carbide, niobium carbide and vanadium carbide, etc., which can make cemented carbide have high hardness and high wear resistance. The binder of cemented carbide is mainly metallic cobalt or metallic nickel, which can ensure that the cemented carbide has a certain strength and toughness.

The main alloy components of cemented carbide plates are WC and C0. The contents of WC and Co in cemented carbide plates for different uses are not consistent, and their use range is extremely wide.

In 1923, Schroeter of Germany added 10% to 20% cobalt as a binder to tungsten carbide powder and invented a new alloy of tungsten carbide and cobalt. Its hardness is second only to diamond. This is the world's artificial alloy. The first cemented carbide. When cutting steel with a tool made of this alloy, the edge will wear out quickly and the edge may even chip. In 1929, Schwarzkopf of the United States added a certain amount of tungsten carbide and titanium carbide compound carbides to the original ingredients to improve the performance of the tool in cutting steel. This is another achievement in the history of cemented carbide development.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

The delivery times (delivery dates or delivery periods) specified by us in the order are binding.

Unless otherwise expressly agreed, delivery times are calculated from the order date.

In the case of frame orders or standing orders, where delivery on demand is agreed upon, delivery times commence from the notification date for the quantities specified in each dispatch notification, unless otherwise expressly agreed.

Normal time for receipt of goods at our designated destination is decisive.

our company

Our first lot of products from the sintering furnace is carbide heading blank dies in 2006

We have independently developed 48 grades and will be more in the future.

We have replaced our equipments twice during 5 years to ensure the quality and improve the efficiency thus decrease the price to be more competitive

our value faith is solve the problem of customers