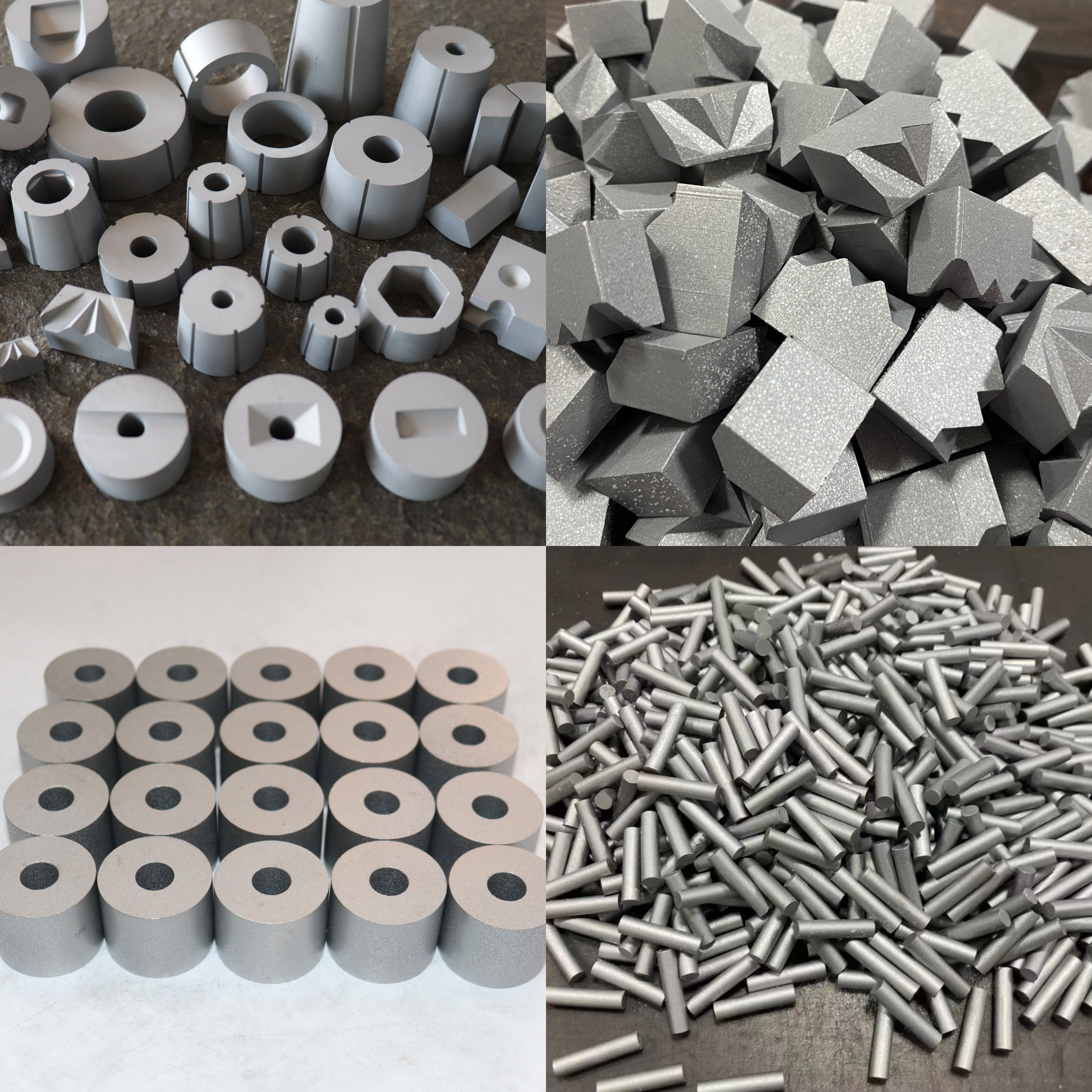

Cemented carbide is a composite material composed of metal carbides, metal oxides and other hard substances and binding agents, which has excellent properties such as high hardness and resistance to wear, and is therefore widely used in many fields. The following are its common uses:

1. carbide tools: carbide has high hardness and wear resistance, and can be used to make drills, milling cutters, gear cutters, etc.

2.tungsten carbide roller : Tungsten carbide rolls are popular in rolling mills for their superior properties and advantages such as:1) Wear resistance: Tungsten carbide rolls are extremely hard, durable and resist wear and tear even at high temperatures.2) High compressive strength: Their high compressive strength enables them to resist deforming under pressure and maintain their shape and surface finish.3) Corrosion resistance: Tungsten carbide rolls are resistant to corrosion from various chemicals and acids.4) High thermal conductivity: Tungsten carbide rolls have a high thermal conductivity, which allows them to transfer heat quickly and resist thermal shock.5) Dimensional stability: These rolls are manufactured to precise tolerances to ensure they maintain their size and shape over time.6) Lower overall maintenance costs: Due to their long service life and reduced need for maintenance, the overall cost of using tungsten carbide rolls is much lower than traditional rolls.7) Increased productivity: Tungsten carbide rolls reduce downtime due to wear and tear, which leads to increased productivity and efficiency in rolling mills.

3. Machinery parts: The high hardness and anti-wear properties of cemented carbide can be used to make machine tool parts, bearings, milling cutters, drills, etc. to improve the service life and efficiency of parts.

4Screw and nut die: Tungsten Carbide Cold Heading Dies for Screws and Nuts that made from 100% Virgin Raw material of WC and CO. With high density, good wear resistance, and high bending strength.

5. Carbide Ring Cutter: Ring cutters made of carbide can be used to make round parts of various materials.

6. Cemented carbide abrasives: With its anti-wear properties and hardness, cemented carbide can be made into abrasives for polishing and grinding of metal surfaces.

In conclusion, cemented carbide has a wide range of applications, especially in areas that require high hardness and wear resistance, such as mining, machining, aerospace, automotive and other manufacturing industries.

Post time: May-04-2023